Vibrant batching plants feature IoT and remote monitoring

By Staff Report | October 21, 2024 2:59 pm SHARE

For the past decade, Vibrant Construction Equipment has been at the forefront of construction innovation and sustainability, providing sophisticated, fuel-efficient asphalt and concrete solutions that fulfil industry expectations while promoting environmentally friendly practices.

As a well-established brand in the construction equipment space, what have been the major milestones for Vibrant over the years?

Over the past ten years, Vibrant Construction Equipments has reached key milestones that showcase our dedication to innovation and excellence in construction equipment. Starting with our first Asphalt Drum Mix and Wet Mix Macadam Plants, we’ve expanded our lineup to include advanced Asphalt Batch Mix and Concrete Batching Plants, strengthening our position in the market. Our R&D team continuously works to bring new, high-quality, and fuel-efficient technologies to our clients. We’ve also introduced asphalt recycling plants for reusing materials and recently launched a coal-fired burner to reduce fuel costs with an advanced pollution control system. With successful projects nationwide and lasting client relationships, each milestone reinforces our commitment to sustainable infrastructure and solidifies our brand’s reputation.

The electronic weighing system is vital to ensuring mix accuracy. How does your system stand out in terms of precision and efficiency compared to competitors?

Our electronic weighing system is engineered with high-precision load cells and advanced software algorithms that ensure consistent mix accuracy across all batches. Unlike standard systems, ours offers real-time calibration, allowing precise control and minimal deviation in ingredient proportions. Additionally, our system’s user-friendly interface enables operators to monitor and adjust the mix quickly, ensuring optimal performance even in high-demand conditions. These features make our system standout in precision and reliability.

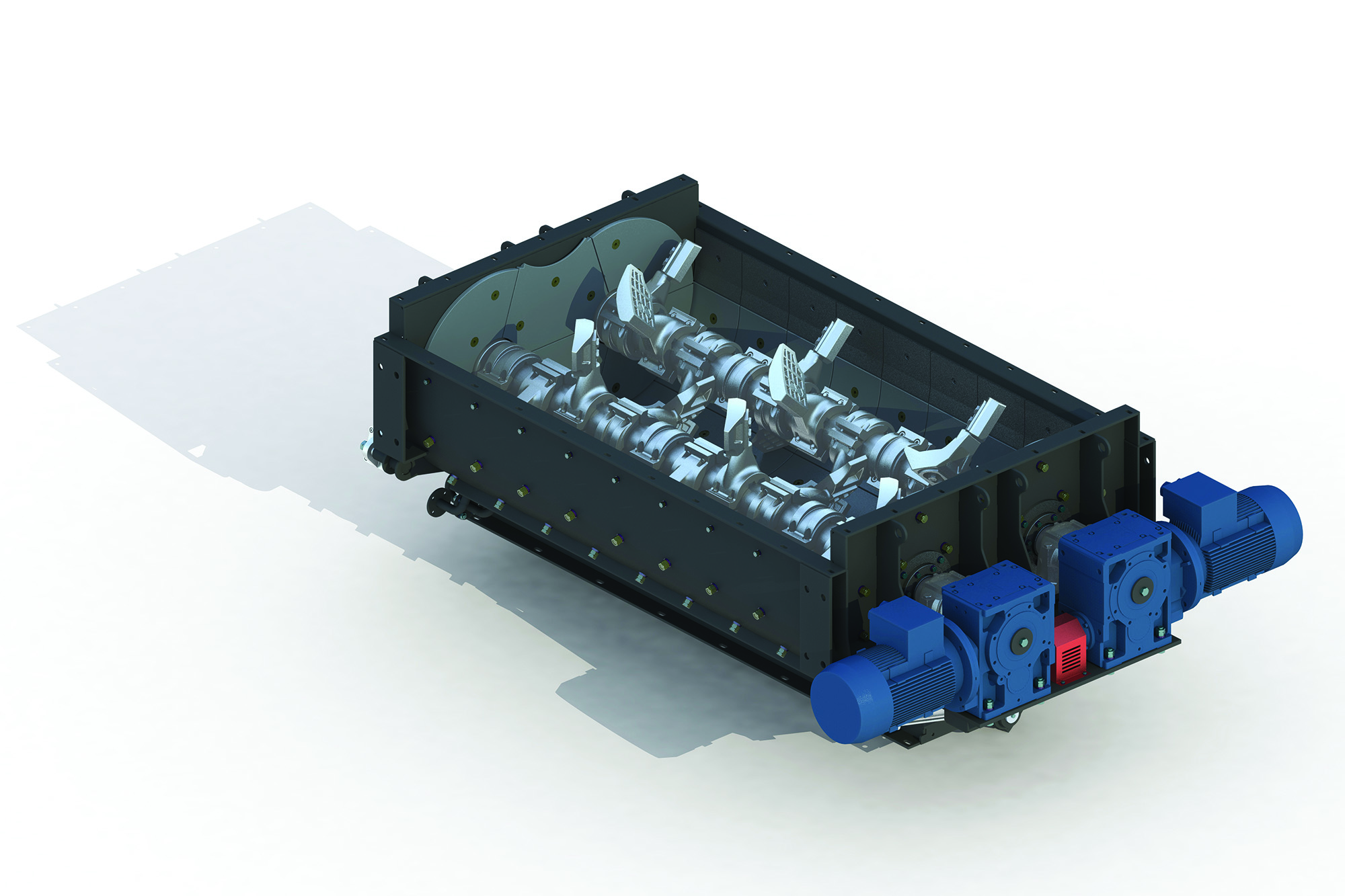

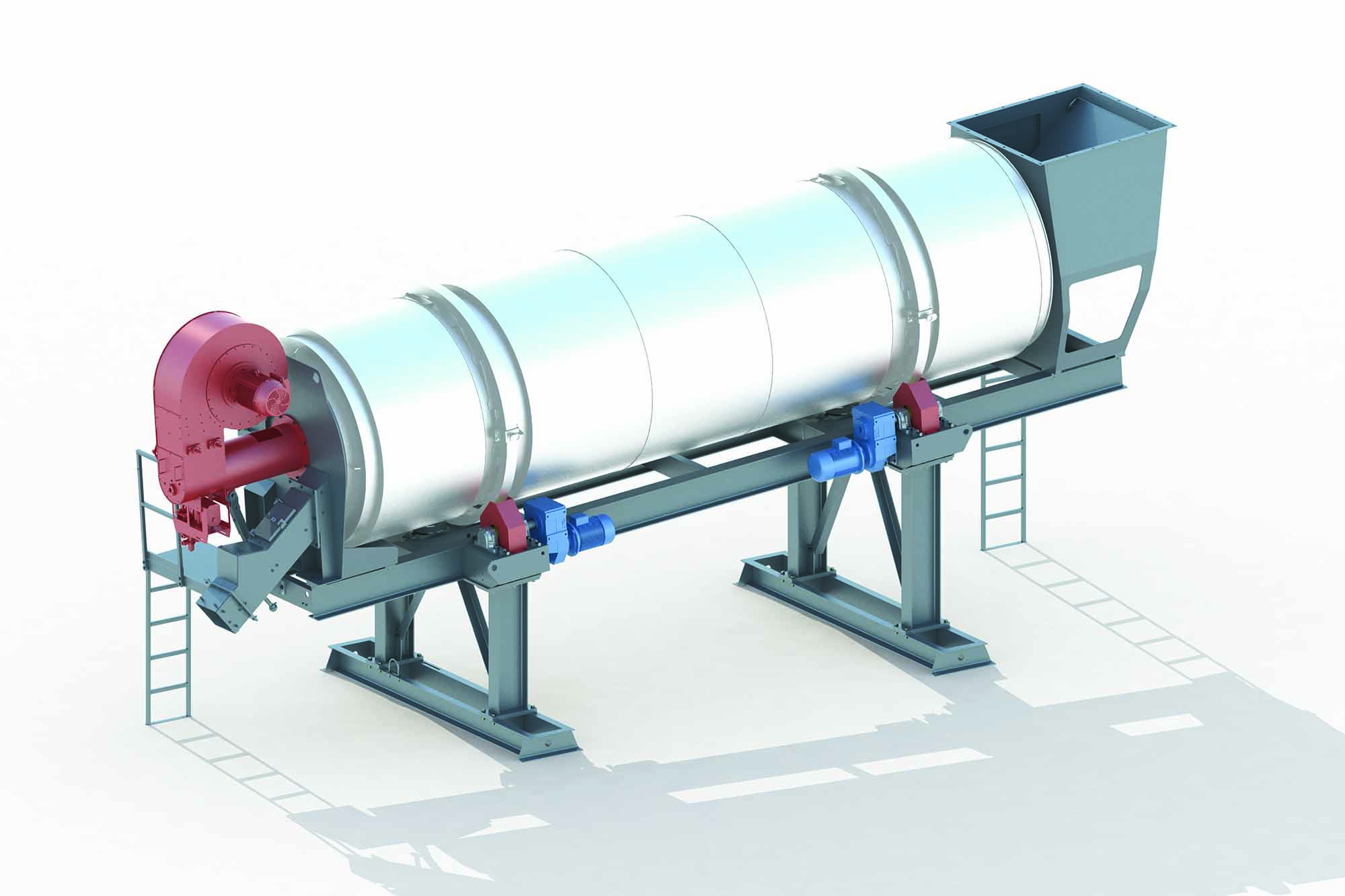

How do the design innovations in the Thermodrum unit and twin shaft mixers contribute to achieving optimal asphalt mix quality with lower fuel consumption?

Our Thermodrum unit and twin-shaft mixers are engineered with a strong focus on energy efficiency and mix quality. The Thermodrum features an advanced heat exchange system that maximises thermal efficiency, ensuring consistent heating while minimising fuel consumption. Its optimised drum design promotes thorough material flow, and added thermal insulation reduces heat loss. Real-time monitoring allows precise temperature control, which prevents overheating and preserves asphalt mix quality. Meanwhile, our twin-shaft mixers provide intensive mixing action, achieving faster blending and producing a high-quality, homogenous mix. Together, these innovations deliver superior asphalt quality with lower fuel costs, enhancing both performance and sustainability.

How is Vibrant contributing to sustainable construction practices, especially regarding fuel efficiency, material reuse, and emissions control in your plants?

At Vibrant, sustainability is the core of our design and manufacturing processes. We enhance fuel efficiency by integrating energy-saving features such as advanced Thermodrum units, thermal insulation, optimised dryer flight design, and high-efficiency multi-fuel burners, significantly reducing fuel consumption. For material reuse, our asphalt recycling plants enable the reprocessing of milled asphalt, cutting down on new material needs and minimising waste. Furthermore, our plants have advanced pollution control systems to monitor and reduce emissions, ensuring compliance with stringent environmental standards. We support eco-friendly construction practices through these innovations, helping our clients build more sustainably.

What are your clients’ common issues in asphalt and concrete batching plant operations, and how does Vibrant solve these operational pain points?

Environmental compliance: Meeting stringent emissions regulations can be challenging, especially with older equipment, and compliance requirements vary by location. We have a standard practice of gathering information on the installation location to ensure our plants meet each state’s specific pollution control norms. We tailor our equipment to align with these requirements and guide clients on any additional measures needed for compliance, offering support to help them achieve full environmental compliance.

Labour skill shortage: A shortage of skilled operators can lead to inefficient handling and operation, impacting productivity and quality. We provide comprehensive training programs to ensure operators are skilled in equipment operation and maintenance, enhancing efficiency and reducing errors due to a lack of knowledge. Our equipment can be IoT-enabled for remote monitoring and diagnostics, offering real-time insights into plant operations.

How do you ensure customers can easily access spare parts and maintenance services, especially in remote project locations?

Ensuring easy access to spare parts and maintenance services, especially in remote project locations, is our top priority. Here’s how we achieve this:

• Centralised inventory management: We maintain a comprehensive inventory of spare parts that can be quickly dispatched, ensuring fast repair turnaround times. We predict spare parts demand through proactive inventory management and data analytics to keep stock levels optimal and readily available. Regular communication with customers allows us to adjust inventory based on their needs.

• Remote diagnostics and monitoring: All our machines are equipped with IoT/SCADA capabilities for remote monitoring. This allows us to diagnose and address potential issues before they escalate, enabling proactive maintenance.

• Scheduled maintenance programs and operator training: We offer tailored maintenance contracts with regular check-ups and services to keep equipment in peak condition. We provide operator training for routine maintenance and minor repairs, reducing reliance on external support and empowering operators with essential skills.

For more information, visit: https://vibrantengineering.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)