We did India’s tallest building demolition

By Edit Team | September 10, 2022 2:14 pm SHARE

Can you please elaborate on your established standards and practices for demolition?

Can you please elaborate on your established standards and practices for demolition?

In India, there are standards that are too old and need change. However, with the transformations in the infrastructure sector, we have seen improvements in standards and planning over the last 15 years. However, it has been observed that the industry is very unorganised or disorganised, controlled by scrap dealing people whose interest is in scrap material rather than how to descend/demolish a building safely.

We’ve been in this business for nearly 12 years, and we’re gradually moving toward mechanised processes to reduce manual labour. Manual labour eventually increases the instances of unsafe activities in the industry. We have recognised the concept of safe demolition. After the first two and a half days of visits to the twin tower site, we were confident that we could do this job, and we were all pleased with how the demolition had gone.

What were the key strategies that you employed during the course?

Twin Towers as it is recognised was surrounded by Aster 2 tower in Emerald Court, and then a gas pipeline ran 4M underground, nearly 16 metres away from the face of the twin tower. These were the two significant challenges. Many engineering calculations were performed using science and math to ensure a precise descent. Following the test blast, we made a few changes in the blast design to ensure that we get the fall right and to a place intended by us. We had to make sure that it wasn’t a freefall but that we could direct the structures to where we wanted them to go and land where we planned them to be after implosion.

What were the critical aspects considered while planning and inspecting the demolition process?

It took us over two months to plan and create. We did some site tours and analysed three factors that could potentially risk the demolition. The first of these three factors is the structure’s lengthy shear walls; the second component is the lift shaft; the third element is the staircase, a structural staircase that could be climbed and descended. So, these three factors are the most important to prepare as it restricts the structure to collapse.

Without proper planning, the structure can go either way. The majority of the structures fail, primarily because of the lift shaft. So here is it: it starts right from the foundations and travels to the top of a structure. So, the structure can go in any direction. It works because it is heavy enough to pull the building in any direction if not prepared right. We must build a robust blast design so that it can be incorporated into the structure in a limited amount of time. The second factor that took time and that we encountered a challenge with was the layout of the structure within. We realise that there are around 2700 aberrant columns within the shape of twin towers.

Moreover, because the bricks are loose, they can fly everywhere. So, by the time we were at the drawing board and planning the overall design, we had taken advantage of the time to remove the bricks and internal partitions, partition walls, and block works.

In these 2700 unusual columns, roughly 9642 holes had been cored drilled. We realise if I extrapolate it to approximately two meters per hole as an average depth, So, we’re talking about nearly 18 kilometres of drilling in the structure.

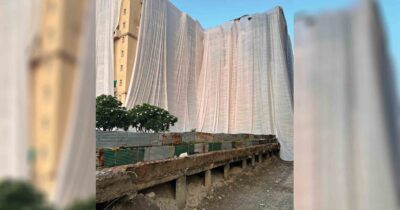

How did Geo Textile fabrics help you contain the spills during the demolition process?

The Chain Links and Geo Textile fabric was wrapped to the column to avoid the flying particles of debris. We’ve completed five layers of chain links, followed by five layers of geotextile material. We were wrapped over a hundred and twenty kilometres of geotextile cloth. And the construction was eventually planned to be a 40-story structure, and yes, the foundations and bottom floors were built strong. So, with the majority of these stumbling hurdles, we had to pop out of it and put together the design in the appropriate style, so we could be sure the fall could be directed in the way we wished.

What extra measures were taken from the structure, and what type of help was provided by the authorities throughout the entire procedure?

The tremor, which the residents around believe could be an earthquake-like vibration, was the main problem however they are currently experiencing tremors almost every year of the earthquake as Noida as a city sits on seismic zone IV. However, we were confident from day one which it couldn’t be as threatening; there has been a third-party vibration evaluation wholly referred to as “vibration predictions” with the aid of a UK-based company. After that, we applied numerous cushioning effects on the ground and inside the basements to reduce the vibrations. For the safety of the surroundings, we have taken up a Rs 100 crore collateral damage insurance policy due to the impact of a fall on the ground. It became the Noida government’s responsibility to install massive labour and machinery so that these roads could be cleaned as soon as possible.

Other than the era and the bomb activities, what kind of gadgets become in location?

We used diamond core drills, on-site electrical drills, breakers, and mini excavators to remove a few partition elements and add a few systems to shift debris from one point to another. Following that, we used the Hilti DX tools to restore those curtains on columns.

Given the volume of waste generated, what steps may be taken to put off and recycle?

Managing the construction rubble and fragments (debris) is always a problem for this project and our other 20 ongoing projects. We have started working on an assignment because it has become stricter regarding disposal. The mandatory government has established standards for the C&D waste that we generate. With the initiation of C&D Waste Management Rules – 2016, debris is now disposed of, as scientifically as possible. The government has begun implementing C&D waste plants to recycle debris in various locations across India.

In terms of our projects in Noida, we expect to generate 70000 to 80,000 tonnes of demolition waste, out of which 400000 to 50,000 tonnes are disposed of in pits and basements, and the remainder is disposed of at the Noida authority’s C&D waste plant, Sector 80, which is privately owned with the assistance of Ramky. And eventually, Ramky would downsize the debris and then make paver blocks or cement blocks, which they would sell or trade on the open market. We will segregate and supply them with pure concrete from our end of size about 250mm.

Recycling, reusing, and sustainability will be great alternatives to removing or switching debris. If a nation no longer has this facility, applying it as a landfill option is the subsequent choice. The level lands, below ground degree, could be landfilled.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)