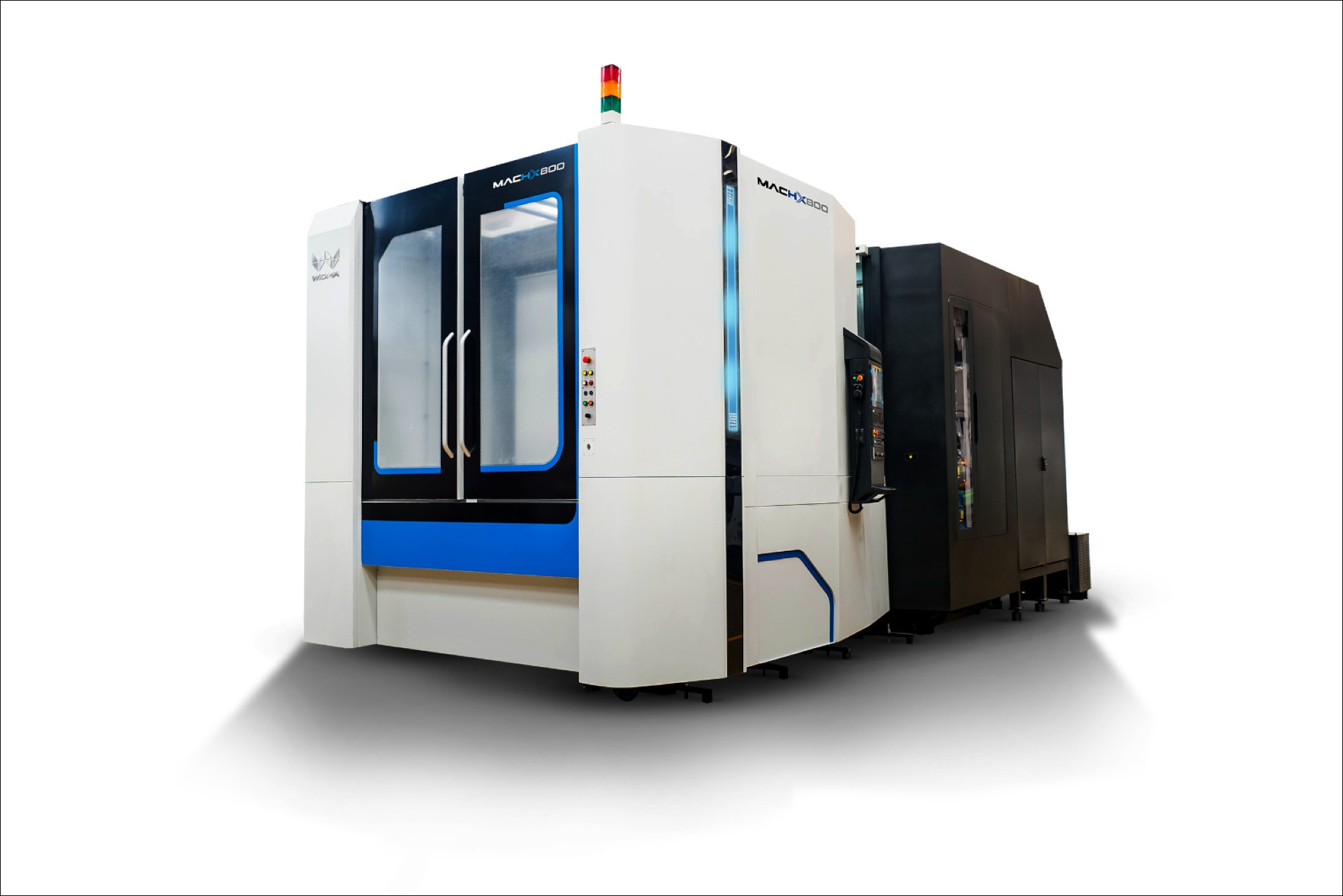

WIDMA introduces next-gen horizontal machining center

By Edit Team | May 18, 2024 11:51 am SHARE

WIDMA introduces next-gen horizontal machining center MacHX800 HMC designed for large part machining and Industry 4.0 environments.

WIDMA® Machining Solutions Group of Kennametal India Limited, a leading manufacturer of metal cutting CNC machines, announced the launch of MacHX800—a standard horizontal machining center (HMC) designed for large part machining across industries including commercial vehicles, construction and farm equipment, aerospace and general engineering. Designed with advanced next-gen features including Industry 4.0 compatibility, this new WIDMA machine delivers the rigidity, productivity, accuracy and versatility to machine a variety of materials in the toughest conditions.

“We are thrilled to announce the addition of Horizontal Machining Centers to our expanding portfolio of innovative standard offerings. The MacHX800 is testament to our decades of experience in delivering customers cutting edge solutions through customised as well as standard machines. These next-gen machines are manufactured in our state-of-the-art facility in Bangalore, India. Leveraging its end-to-end capabilities and stringent process adherence as per Kennametal global standards, our machines ensure optimum quality with consistent performance,” says Vijaykrishnan Venkatesan, Managing Director, Kennametal India Limited.

The MacHX800 is designed specifically to machine complex large components and deliver productivity in the most demanding conditions, including:

- Incredible accuracy and precision to optimise productivity and manage costs per component

- User-friendly features to help operators load/unload and machine massive components with ease, upholding benchmarked standards of ergonomics and safety

- Integrates with Industry 4.0 environments

WIDMA’s MacHX800 combines the advantages of plug and play features with the flexibility of customising several offerings like choice of spindles, pallets and tool magazines enabling customers to achieve machining goals. “All put together, MacHX800 is engineered for machining tomorrow, enabling us to partner with our customers to solve their toughest productivity challenges,” adds Vijaykrishnan.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)