We provide customised concrete solutions for every stage of construction, from the roof to the foundation, says Dhanbir Singh Suri, Co-Founder, Concretech India.

Can you tell us about your RMC construction solutions and offerings?

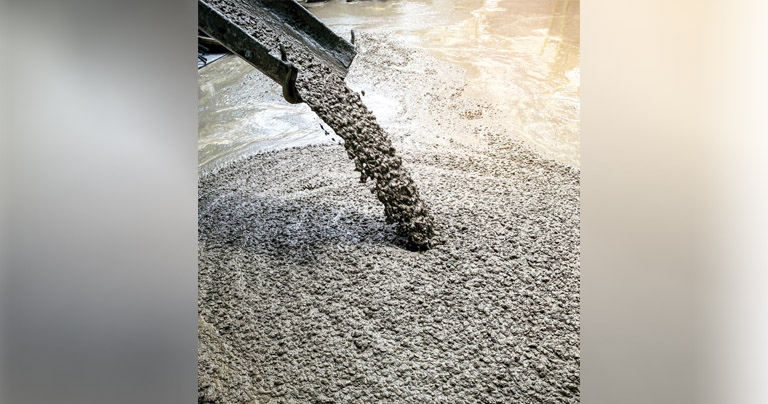

Concretech India has been a Mumbai-based company since 2005. Our core business is the efficient production and distribution of high-quality ready-mix concrete and bitumen, primarily in the construction industry, that meets the specifications of the specifiers.

How are supply chain issues affecting the highest quality and most sought-after concrete equipment services?

We have a vast fleet of Transit mixers and concrete pumps, which helps us to deliver customer delight and negate supply chain issues. We have our bulkers, Hyva Trucks, for inbound logistics. We are self-reliant regarding supply chain management, and long-term tie-ups with trusted suppliers help us overcome supply chain issues.

What are the difficulties in obtaining raw materials to develop and manufacture RMCs and aggregates for Indian infrastructure needs?

Cement, fly ash, aggregate, and additive constituents are the primary raw materials used in our product mix design. Most of these raw materials are backwards integrated by us, enabling us to provide clients with products of the highest calibre. Most of these raw materials are limits and far from our production facilities. Thus, any delay in the delivery of raw materials significantly impacts our production facilities. Any variation in the quality of internal raw materials may have a ripple effect across the entire production process.

What kinds of products and services do you provide? And how are price fluctuations affecting your business?

We offer tailored concrete solutions for every stage of construction, from the roof to the foundation –

• Ordinary-M-10, M-15, M-20

• Standard-M-25, M-30, M-35, M-40, M-45, M-50, M-55

• High Strength-M-60, M-70, M-75

High-strength concrete for high-rise buildings has been our preferred concrete solution. We also have a significant share of concrete in MCGM projects, where most of our pavement quality concrete is used, thereby contributing to nation-building. Our industry is highly price sensitive, and any change in cement prices directly impacts the final price of our product. The current rise in crude prices as a result of the Ukraine conflict has had a significant impact on our fleet costs.

Could you please describe your organisation’s sustainability practices?

Concrete India is dedicated to creating a greener and more sustainable world. We have implemented a sustainable strategy throughout all of our supply chains. We are an ISO-accredited company along with the Quality Council of India Certificate. We use recycled water for plant cleaning and maintenance. The use of supplementary cementitious material assists us in designing eco-friendly concrete, which in turn helps our client obtain green ratings. Our R&D team is currently developing carbon-neutral concrete, which would be one of the first in our region.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.