The welding sector’s rapid growth, fuelled by infrastructure development and industrial activity, presents considerable prospects for manufacturers such as GEE Limited. With its 100 percent “Make in India” stainless steel electrode products, GEE Limited is well-positioned to capitalise on the spike in demand.

For almost six decades, GEE Limited has been a veteran in the Indian welding business, specialising in high-quality welding equipment and customised electrodes to meet the different needs of its customers. GEE Limited has established itself as a trusted market organisation via an uncompromising dedication to innovation, quality, and client satisfaction. The company adheres to a 100 percent “Make in India” culture, coinciding with national objectives to strengthen domestic manufacturing and lower import dependency. Our tagline, “Seal of Trust,” is based on constantly delivering items that fulfil high-quality requirements.

GEE Limited has significantly contributed to the welding industry, as evidenced by its exclusive use of Indian electrodes in constructing Dubai’s renowned Burj Khalifa Towers. Their breakthroughs include specialised electrodes such as GRIDUCT 100 for welding alloys like DMR 249A and DMR 249B, critical in constructing the indigenous aircraft carrier INS Vikrant. They’ve created cutting-edge solutions such as the E9015 B91 electrode for Creep Resistance martensitic steel and the ENiCrMo 14 electrode for GE Power, known for reducing emissions in thermal power plants. These achievements demonstrate GEE Limited’s global leadership in providing innovative welding solutions.

They substantially contribute to India’s industrial landscape by delivering cutting-edge welding solutions for various industries, including autos, Indian defence, infrastructure, power generation, cement manufacturing, oil & gas, railways, major shipyards, and refineries. Their cutting-edge production facilities in Kalyan and Kolkata are outfitted with sophisticated automated machinery acquired from Germany. The Kolkata facility, with the greatest floor space in the industry, is one of the largest facilities of its sort in India. Their wide product offering includes over 500 customised welding consumables that meet demanding industrial criteria while addressing crucial weld metal properties. With the help of a strong R&D team, they rigorously analyse our customers’ welding difficulties before proposing specific solutions in welding methods and unique formulations of welding consumables. Their products have received recognition and endorsements from key industry groups, including ABS, BV, DNV, LRS, IRS, IBR, RDSO, TOYO, BHEL, NTPC, TATA, JINDAL, L&T, and many more, cementing our name as a reliable partner in welding technology and solutions. GEE Limited’s comprehensive product line serves a variety of industrial sectors. The company’s welding technology competence and commitment to producing high-quality goods have helped it establish itself as a prominent producer.

Growth in the SS Welding Market

The stainless steel welding market is experiencing strong growth owing to fast infrastructural development and industrial expansion. Construction, infrastructure, shipbuilding, food and beverage, and chemical and petrochemical industries contribute to India’s economic growth.

GEE Limited is well-positioned to handle this growing demand thanks to its innovative production capabilities and unwavering dedication to quality. By producing high-quality SS electrodes locally, GEE Limited not only supports the domestic market but also decreases dependency on imported goods, helping to grow India’s economy.

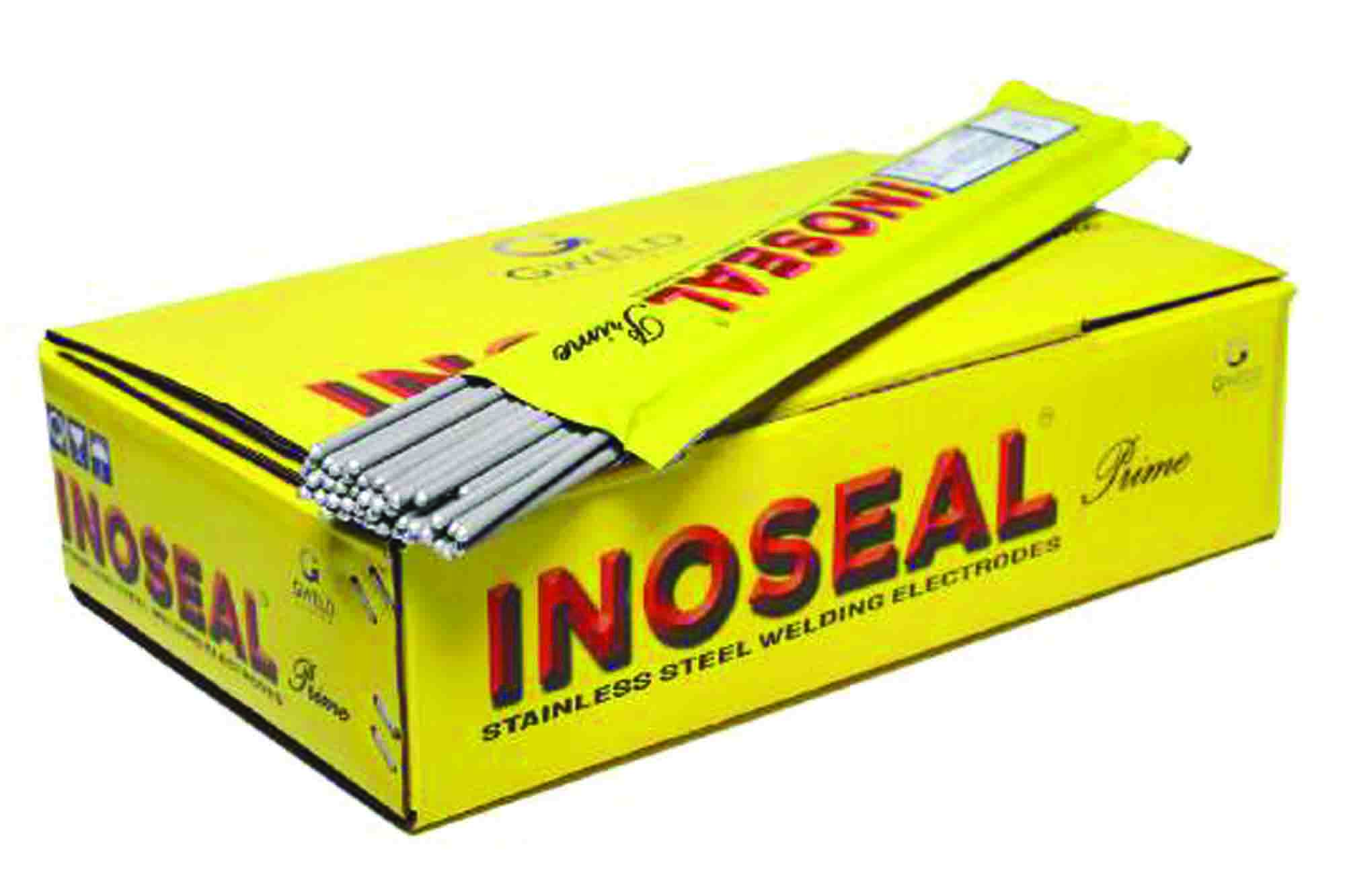

INOSEAL PRIME stainless steel electrodes: Innovating welding solutions

GEE Limited’s latest product, the Inoseal Prime SS Electrodes, marks a substantial advancement in welding technique. These electrodes are specifically designed to satisfy the increasing demands of the Indian market, providing exceptional performance across a wide range of industrial applications. The Inoseal Prime SS Electrodes are designed for welder-friendly operations. This improves operational efficiency, shortens post-weld cleanup time, and increases production.

Introducing the Inoseal Prime SS Electrodes demonstrates GEE Limited’s dedication to providing cutting-edge, high-quality welding solutions. By focusing on the specific needs of the Indian market and following high manufacturing standards, GEE Limited maintains its welding industry leadership. These electrodes, known for their remarkable performance and versatility, are set to become the preferred option of specialists in industries such as construction, shipbuilding, food and beverage, and chemical and petrochemical facilities.

GEE Limited’s strategic vision and commitment to quality have established it as a pioneer in the welding industry. The introduction of the Inoseal Prime SS Electrodes positions the company to expand its market presence and address India’s growing need for high-quality welding solutions. As infrastructure and industrial operations rise, GEE Limited’s innovative products will play an important role in supporting and developing the country’s industrial development. The company’s dedication to manufacturing 100 percent “Make in India” products boosts the home market while aligning with national goals to develop self-reliance and economic development.

In summary, GEE Limited’s unwavering commitment to innovation, quality, and customer satisfaction, together with its ground-breaking Inoseal Prime SS Electrode line, places the company at the forefront of the developing SS welding market. As the need for high-quality welding solutions increases, GEE Limited stays committed to providing cutting-edge products that promote industry excellence and contribute to India’s industrial success.

For more information, visit: https://www.geelimited.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.