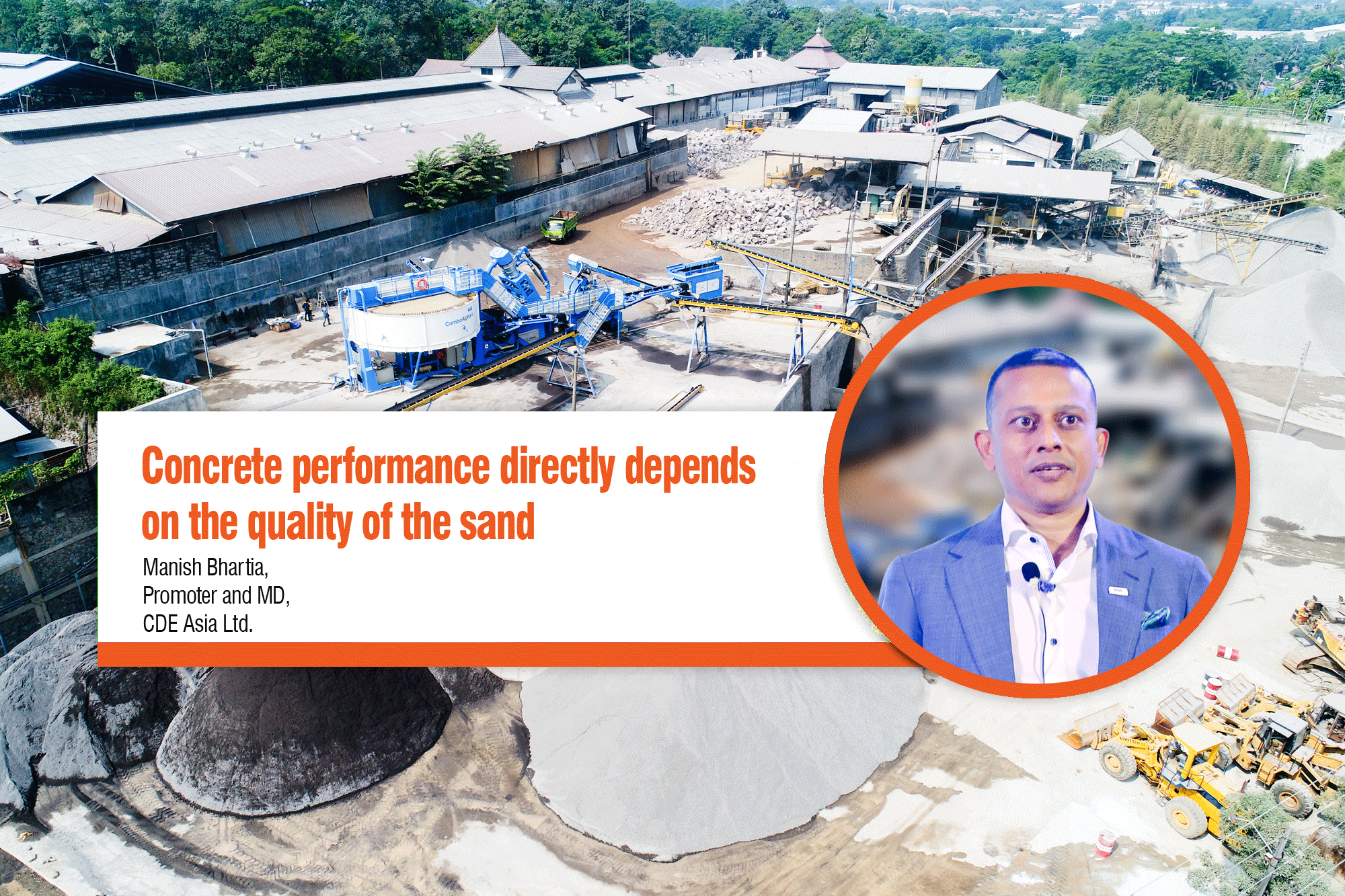

Concrete performance directly depends on the quality of the sand

By Edit Team | December 19, 2019 5:33 am SHARE

More and more construction companies now choose the safe, quality option of washed sands that are made to their exact specifications.

What is your expectation from the upcoming edition of Excon?

This is the first time we are featuring our Combo technology at Excon 2019. We hope it will provide us an effective platform to reach out to a large number of construction companies, mining and quarries operators many of whom are already using CDE wet processing products and have been able to enhance their offering in terms of grades, value for money, quantities and delivery time. In short, they have not looked back.

What are the advantages of using CDE washed manufactured sand?

As concrete performance directly depends on the quality of the sand used in the mix, more and more construction companies now choose the safe, quality option of washed sands that are made to their exact specifications. Choosing unwashed crusher fines often leads to adding more chemical and mixtures to compensate for poor quality sand.

Better, sand results in better and stronger concrete. It has been demonstrated that the use of CDE sand in the mix will greatly increase your concrete’s compressive strength and therefore workability when compared to VSI crusher fines. In the same vein, levels of flexural and split tensile strength when using CDE sand have shown to jump ahead of levels achieved by VSI crusher fines by up 19 per cent. Cement is expensive. Indicative of the cost-saving aspect of sand washing, CDE washed concrete sands compare favorably to unwashed crusher fines when looking at the weight required in the mix proportion. It takes 355 kg/cum of VSI crusher fines to catch up with the result only 300 kg/cum of CDE washed sand achieves.

How does CDE Asia’s washing plant make the job easier?

Developed specially for the m-sand production CDE Asia’s patented Combo eco-friendly technology integrates all washing processes from end-to-end in a single compact mobile unit. The plant, with its cutting-edge technology, gives accurate control of silt cut points to deliver high-quality sand. With a wide range of production capability of 50-200 tons per hour, provides an attractive proposition to the maturing washed m-sand market across Asia. In fact, our washed m-sand is a preferred choice as it is a viable alternative to river sand. With the spurt in construction projects, the larger companies are regularly demanding high capacity plants to meet their sand requirement. Combo provides the perfect solution in meeting their need for an integrated mobile wash system which allows operators the flexibility to produce concrete or plaster sand, from one machine.

The combo technology can be applied for washing a wide range of materials including m-sand, crushed rock fines, natural sand, gravel, etc. Due to its mobility, there is no requirement for bulky civil and structural work and the associated time-consuming process of dismantling and reinstallation. Companies engaged in quarrying in different geographic locations can move the plant as per their requirement, plus the plant can be commissioned onsite in just less than 7 days.

What elements make CDE washing plants technology ecologically friendly?

Our innovations demonstrate CDE’s commitment to help customers achieve the highest sand specifications, using washing technologies, while ensuring minimum impact on our environment. Combo® requires a small supply of freshwater as opposed to traditional systems which typically consume 10-15 times more water. This is what makes the Combo the eco-friendliest sand washing system in the world. Wastewater from the system is transferred to the inbuilt recycling unit, where the solids are separated from the water. 95 percent of water is recycled and circulated back into the plant and the final waste silt is removed from the recycling unit in the form of concentrated sludge for easy recovery through the integrated Easy Settle sludge management system. The technology to convert sludge into light-weight bricks for construction use is also provided by the CDE TechCenter. The other significant advantage is the low power consumption of 0.85kW per ton of feed makes it the most power-efficient machine using clean energy.

What products will you feature at Excon? Tell us something about it?

We are showcasing our all-new Combo X70 Smart featuring an intelligent remote monitoring platform and range of smart features. It enables real-time measurement of critical functions, storage of equipment-usage data for accurate diagnosis during service calls, and broadcast of user warnings for service requirement. It assists users in getting maximum plant performance with maximum equipment availability, such that customers can meet and exceed their production targets.

Manish Bhartia, Promoter and MD, CDE Asia Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)