Connecting North India through Eastern Peripheral Expressway

By Edit Team | February 14, 2020 6:27 am SHARE

Eastern Peripheral Expressway, which is India’s first green and smart project has been delivered at express speed. It has been powered by 87 machines of Schwing Stetter India.

Project description:

This 135 Km, India‘s first green, smart Eastern Peripheral Expressway (EPE) aims to decongest Delhi thereby reducing pollution. It will bypass Delhi on the eastern side and covers Haryana, Delhi and Uttar Pradesh. The expressway will provide connectivity between Delhi and the towns of Ghaziabad, Faridabad, Greater Noida and Sonipat. The project involves construction of a six-lane expressway with access control from Faridabad to Sonipat. The expressway will have two sections, the 56 km-long Faridabad – Ghaziabad section and the 49 km-long Ghaziabad – Sonipat section. The completed expressway will help relieve traffic congestion in the Faridabad – Ghaziabad stretch.

This project is being constructed by Ashoka Buildcon, Gayatri Projects, Jaiprakash Associates, Oriental Structural Engineers and Sadbhav Engineering. The project execution was divided into six packages – 21-km stretch in Sonepat-Baghpat, 24.5 km stretch in Baghpat-Ghaziabad, 24.5-km stretch in Ghaziabad-GB Nagar, 22-km stretch in GB Nagar, 21-km stretch in GN Nagar-Faridabad and 22-km stretch in Faridabad-Palwal.

Concreting at EPE:

In order to stick to the deadlines issued by the Government of India, the project execution team of Ashoka Buildcon, Gayatri Projects, Jaiprakash Associates, Oriental Structural Engineers and Sadbhav Engineering chose Schwing Stetter India equipment as it’s known for its meticulous quality, efficiency, longevity and remarkable customer feedback.

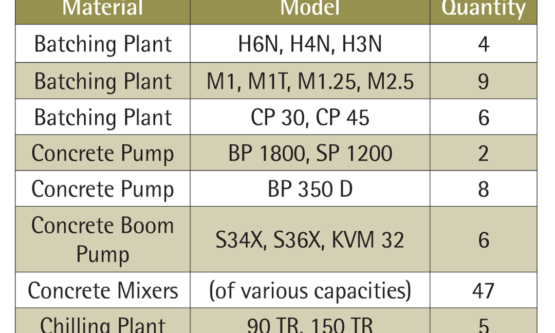

A crucial role has been played by the concreting equipment. A total of eighty three concreting equipment; nineteen numbers of Stetter batching plants along with five numbers of Stetter chilling plant, forty seven numbers of Stetter transit mixers of various capacities ranging from 6 m3 to 10 m3, ten numbers of Schwing stationary concrete pumps and six numbers of Schwing truck mounted concrete boom pumps were at action to batch mix, transport, pour and place concrete in the Expressway with a record breaking in 18 months project completion period compared to the targeted 30 months’ period.

The massive initiative has eight interchanges, 46 small bridges, 151 pedestrian trails, 141 culvert, four flyovers, 71 vehicle underpasses, and eight RoB’s—a total of 400 structures, out of which two major bridges are on the rivers Yamuna and Hindon were built with concrete using Schwing Stetter India equipment.

It took a massive five lakh tonnes of cement, one lakh tonne of steel and a total volume of concrete that was poured and produced is around 20 lakh m3 for this project. Schwing Stetter India equipment in use at this project are listed below.

Concreting Record Creation:

On November 24, 2017, two Stetter Concrete Batching Plant M2.5 were utilised non-stop to produce a total volume of 6750 m3 of pavement quality concrete in a single working day to create a never surpassed “New World Record” in the Eastern Peripheral Expressway project through the execution by Sadbhav Engineering.

Smart and Green Expressway

The expressway is equipped with the latest, world class smart technology and road safety features like intelligent highway traffic management system, variable message signs, CCTV, warning devices, over speed checking system, weigh-in-motion, pavement management systems and fiber optic network, real time video incident detection system and a closed tolling system where the toll will be charged on the distance travelled.

To make this expressway, 20 countries of the world have been studied. This is India’s first such expressway in which the weight of the vehicles will be made before reaching the entry point and it will be dealt with whether the entry of the said vehicle is within the limit. Interestingly, if the vehicle overload is found then the exit gate will open automatically instead of the entry point. It is the country’s first green highway, with landscaping, plantation with nearly 2.5 lakh trees and fully lit by solar energy 100 per cent. There is provision for rainwater harvesting every 500 metres on either side of the expressway, with watering of the plants being done via drip irrigation.

Along the expressway’s length, there are wayside amenities like petrol pumps, rest areas, hotels, restaurants, shops, repair services, etc. There are ambulances and cranes on this expressway at every 20 kilometers. At every 2.5 km, there are toilets-keeping in line with the Swachh Bharat mission. While passing on the Eastern Peripheral Expressway, one will be able to see 36 monuments from the air temperature to the Qutub Minar, Hawa Mahal, India Gate, Lalkila, four Minarets, Jallianwala Bagh, Ashok Chakra, Kirti Colony etc.

Specification:

Name of Project: Eastern Peripheral Expressway.

Name of Customer: Ashoka Buildcon, Gayatri Projects, Jaiprakash Associates, Oriental Structural Engineers and Sadbhav Engineering.

SSI Equipment: 19 batching plants, 5 chilling plants, 47 transit mixers, 10 stationary concrete pumps and 6 concrete boom pumps.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)