Construction operations will soon shift to Industry 5.0 with digitalisation

By Edit Team | February 8, 2023 11:33 am SHARE

Nishit Behera, Executive Director-Business Development & Strategy, RSB Group, in an exclusive interview with Megha Iyer of B2B Purchase, talks about moving from mass production to custom manufacturing with digitisation and intelligentisation.

What is going to be your focus in 2023?

India is expected to have robust demand and is expected to become the third-largest global player in the CE market. With the establishment of a new quadrilateral global economic forum to focus on infrastructure projects and strengthen bilateral cooperation, coupled with infrastructure for resilient island states, India has huge potential to grow on the export front with component manufacture comparatively priced on the lower side.

Besides, on the domestic front, fiscal policy to “Housing for All” and “Smart Cities Mission”, will boost the CE industry to growth ascendance. With huge investment in infrastructure for multi-modal activity with a goal of developing infrastructure to lower logistic costs and improve the economy, the day of glory of the CE industry will be back in full thrust with policy support from the government in establishing the National Bank for Financing Infrastructure & Development (NaBFID) to ensure the adequacy of funds.

We have an impressive client portfolio of leading key global players, TATA Hitachi, Caterpillar, Komatsu, JCB, XCMG, Kobelco., etc and some more will be added in due course once we expand our facilities at different locations of our plants at Jamshedpur, Dhawad, Chennai and Sri City. Our plant at Sri City has just gone into the stream to cater to OEMs.

The construction equipment sector and the government in India are working together to improve indigenisation. How do you assess India’s export potential in this context?

CE components manufactured in India have a massive price advantage and with the establishment of a new quadrilateral global economic forum to focus on infrastructure projects and strengthen bilateral cooperation, coupled with infrastructure for resilient island states, India has huge potential to grow in the export market with anticipated multi-billion dollar hit.

Which equipment/products/solutions and developments, in your opinion, will drive the industry’s shift to sustainable construction?

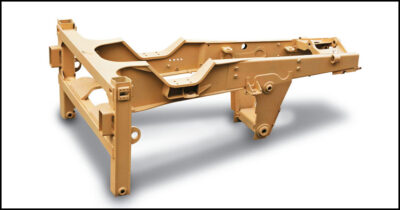

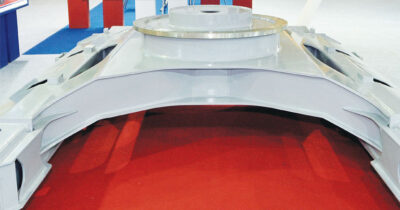

Major precision and heavy fabrication machine components for CEs such as main frame, chassis, track frame, boom, arm, bucket, front-end loaders such as front and rear frame, lift arm and BHL, track type tractor, paving equipment etc. for infra, irrigation, farming and large excavator used in mining. These are the main ingredients of sustenance.

What are your thoughts on digitalising construction operations in the coming years?

Now industry 4.0 is getting graduated into 5.0 where digitisation of operations is going to be the rule of the game and is rightly christened as the 5th Industrial Revolution – an off-shoot of innovation from the lessons taught by Covid-19 which had brought CE industry literally to a stand-still.

It will be a mass personalisation with Artificial Intelligence. It is expected to revolutionise the production process with higher autonomy for collaborative robots and bring in more creativity and innovation in the products by allowing robots to perform repetitive tasks. It is expected to utilise the creative intellectual capability of humans optimally. Moving from mass production to custom manufacturing, the need for today’s sector, is fast progressing in manufacturing techniques, production system digitisation and intelligentisation.

Robots make an enormous contribution to work such as loading, unloading, painting, welding, etc. An autonomous robot can conduct a more accurate independent technique of manufacturing and operate in locations where human employees are limited to operating. A major trend is a cooperative robot, or so-called “COBOT” intended to operate with human employees to assist them with a multitude of duties. Industry 5.0 has devices interconnected to optimise productivity and human effectiveness. Cumulatively it will be a giant leap in productivity in scale, qualitatively/quantitatively with the least human intervention.

The role of Big Data and AI will be significant. In order to generate symmetrical innovation, it can acquire logical derivatives from big data from a network of digital knowledge with precision and performance while cooperative robots can be used on the machine to perform distinctive operations. Big Data will enable information volume, information variety, information value, speed of creation of fresh information and interpretation with IoT sensor-equipped machines to transmit data to other machines and computer systems to make a smarter decision in a split of very low time frame.

Besides, computer peripherals fitted on the machines at the various sites will transmit data through the cloud. the health of equipment and warning signals, including a potential breakdown and predictive maintenance.

How are you addressing infrastructure project safety and project management requirements?

Safety is in-built in our every management schedule of projects. Ours is an ISO-14001 (Environment) and ISO 45001(OHSAS) certified by a global audit firm from Germany, UL DQS, besides our Jamshedpur Unit certified for world-renowned TPM from Japan Institute of Plant Maintenance.

Our every activity is measured in the scale of Aspect/Impact analysis for Environment and Hazard Identification and Risk Analysis (HIRA) with standard operating procedures firmly embedded in every operation and monitoring/measurement controls in place – all put into Deming PDCA Cycle and Continual Improvement month-on-month Kaizen projects. Since Safety is built on the Poke-Yoke principle (Mistake-Proofing), there is practically no iota of compromise on safety culture at all our locations.

What are environmental safeguards in place to manage carbon footprints?

As I said above, our ISO-14001-certified company for the environment and environmental safeguards are on firm footing with pollution, emission, land contamination and resource depletion with every month monitored through on-site validated environment reports by the externally government-approved agency from Central Pollution Control Board. Besides, our internal audits from Cross-Functional-Teams at planned intervals ensure that gaps, if any, are analysed for severity through unavoidable slips, trips or falls, and eliminated forthwith at the source of occurrence with the effectiveness of implementation monitored by the neutral internal audit firm.

Our carbon footprints, thus, meet global and statutory requirements.

For more details visit: https://www.rsbglobal.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)