Jaws Tech continues to establish industry standards and propel the success of mining and crushing operations worldwide with an ongoing commitment to pushing the limits of toughness and effectiveness.

Finding durable and reliable polyurethane products is essential in the demanding worlds of crushing and mining. Look no further than Jaws Tech Engineering, a leading manufacturer that provides cutting-edge polyurethane solutions. With a strong commitment to quality and innovation, Jaws Tech strives to push its products’ boundaries of durability and efficiency.

Commitment to Quality and Innovation

At Jaws Tech Engineering, excellence is not just a goal; it is the driving force behind their exceptional products. With a team of skilled engineers and material scientists, the company invests in extensive research and development to create advanced polyurethane formulations that surpass industry standards. This dedication to quality and innovation ensures that customers receive reliable and high-performing products.

Tailor-Made Solutions for Unique Challenges

Crushing and mining operations face unique challenges, so Jaws Tech adopts a personalised approach to design and production. Whether it’s wearing liners for crushers, polyurethane screens for screening media, or conveyor belt components for material handling, the experts at Jaws Tech work closely with customers to understand their specific requirements. This results in tailor-made solutions that perfectly fit their equipment, enhancing efficiency and effectiveness.

Polyurethane Products and Their Exemplary Benefits

Jaws Tech Engineering’s polyurethane products offer a wide range of benefits:

Unmatched Wear Resistance: Engineered to excel in high-wear environments, these products significantly reduce equipment downtime and maintenance costs, ensuring maximum productivity.

Enhanced Impact Resistance: Jaws Tech’s polyurethane products can absorb and disperse impact energy, providing reliable protection for equipment and ensuring consistent performance.

Optimised Efficiency: These products improve mining and crushing processes through innovative designs and formulations, enhancing overall productivity and profitability.

Minimised Downtime: The durability of Jaws Tech’s long-lasting polyurethane components allows them to withstand the most demanding conditions, effectively reducing unplanned downtime across the equipment.

Innovating for the Mining and Aggregate Industries through Polyurethane

Jaws Tech Engineering is a pioneer in polyurethane solutions for the mining and aggregate industries. Some of their innovative breakthroughs include:

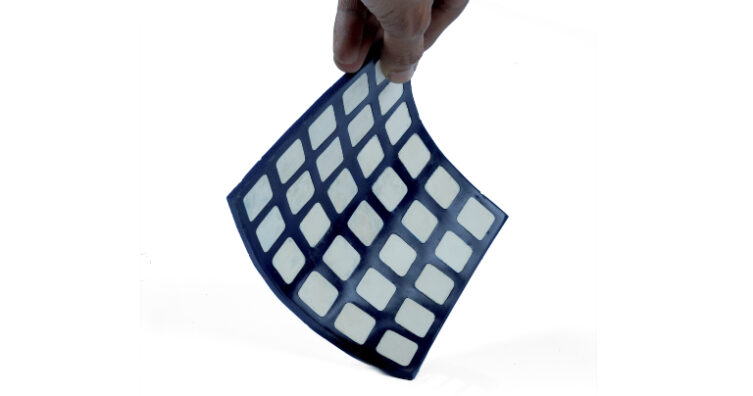

Advanced Polyurethane Screen Technology: The company’s commitment to R&D in polyurethane screen technology has increased abrasion resistance, open area, and improved efficiency in screening and separating materials in mining operations.

Custom-Formulated Polyurethane Solutions: Innovations have led to tailor-made polyurethane formulations designed to withstand the unique challenges of crushing and mining applications. These custom-designed solutions optimise the wear resistance and durability of specific equipment.

Modular Polyurethane Liners: Advancements in modular polyurethane liners for crushers and mills simplify installations and replacements, reducing equipment downtime and maintenance costs. These liners offer improved impact and abrasion resistance, extending the lifespan of the equipment.

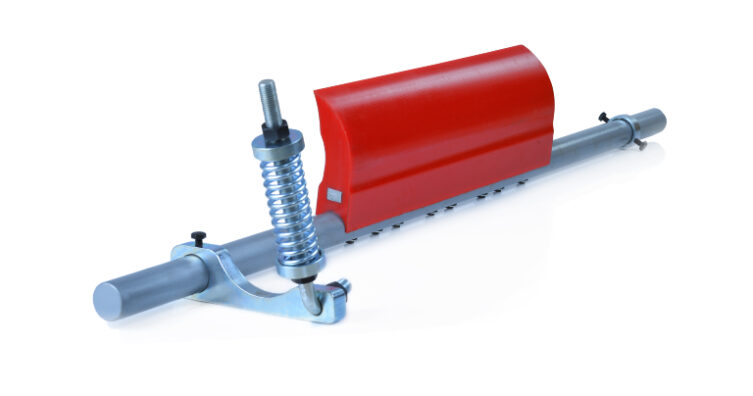

Innovative Conveyor Belt Components: Jaws Tech has developed new polyurethane-based conveyor belt components, including impact bars, skirting, and scrapers. These components enhance material containment, reduce spillage, and improve the system’s performance.

Polyurethane Foam Applications: Innovations in polyurethane foam technology result in better insulation materials for extreme mining environments, regulating temperature and reducing energy consumption.

Wear-Resistant Polyurethane Coatings: The company’s advanced polyurethane coatings provide superior wear resistance for critical mining equipment like chutes, hoppers, and transfer points, reducing maintenance and downtime.

Polyurethane Injection Solutions for Ground Stabilisation: In underground mining, polyurethane injection solutions are used for ground stabilisation and reinforcement, enhancing safety and structural integrity.

Elastomeric Polyurethane Components: Developments in elastomeric polyurethane components, such as springs and couplings, improve shock absorption and vibration dampening in mining equipment, enhancing equipment performance and operator comfort.

Enabling Sustainability

Jaws Tech Engineering is dedicated to product innovation, sustainability, and environmental responsibility. The company invests in research to innovate eco-friendly materials and processes, ensuring their products align with corporate social responsibility goals.

Global Manufacturing Capabilities

Based in Kerala, India, Jaws Tech Engineering boasts global manufacturing facilities and a vast distribution network. This allows them to efficiently serve clients worldwide, regardless of the scale of their mining or crushing operations. With a team of technical experts, Jaws Tech ensures prompt and reliable support for its global clientele.

For more details:

Email id: sales@jawstechengineering.in

Visit: www.JawsTechengineering.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.