Explaining the effect of corrosion on the structural durability and reliability

Concrete the versatile construction medium is, however, degradable under environmental effects. Generally concrete structures have steel as reinforcement for its own inherent low tensile strength. The environmental effects can lead to degradation of the reinforcing steel and this degradation is termed as corrosion due to environment.

Environment means the surrounding to which the concrete structure will be subjected to during its service life. Depending upon the environment the protection system will vary because the requirement for protection is different. Thus a structure which is to be protected for normal atmospheric surroundings will definitely require a different protection system compared to the requirement of a structure which stores fully saturated common salt solution.

Corrosion of steel in concrete reduces the life and durability of concrete structures. It is a worldwide problem, which causes heavy losses to the economy and industry. The corrosion of steel is inevitable. The durability of concrete structures primarily depends on the condition of the embedded steel in concrete, apart from any deterioration that the concrete may undergo.

Corrosion is technically, oxidation of metals, initiated by the reaction of Oxygen with the Metal in presence of moisture. It is also known as electrochemical degradation of metals and alloys due to reaction with their environment. It is accelerated by the presence of acids or bases (alkalis)

All metals corrode over time when exposed to moisture and in a tropical country like India the intensity of corrosion is very high at some places. The metals are subjected to corrosion due o high humidity, exhaust emissions, seasonal temperature variations, industrial chemicals, chloride and sulphate attacks. Steel is most commonly and widely used metal in structures.

Indian scenario

As in today’s scenario there is major emphasis on infrastructure development thus quite a large number of structures with steel, reinforced concrete and prestressed concrete would be constructed in these programmes of infrastructure development, the material used in which is prone to corrosion. A large number of bridges in India are also constructed of steel, besides conventional reinforced concrete or pre-stressed concrete. Many of these bridges become structurally deficient because of corroded steel and steel reinforcement.

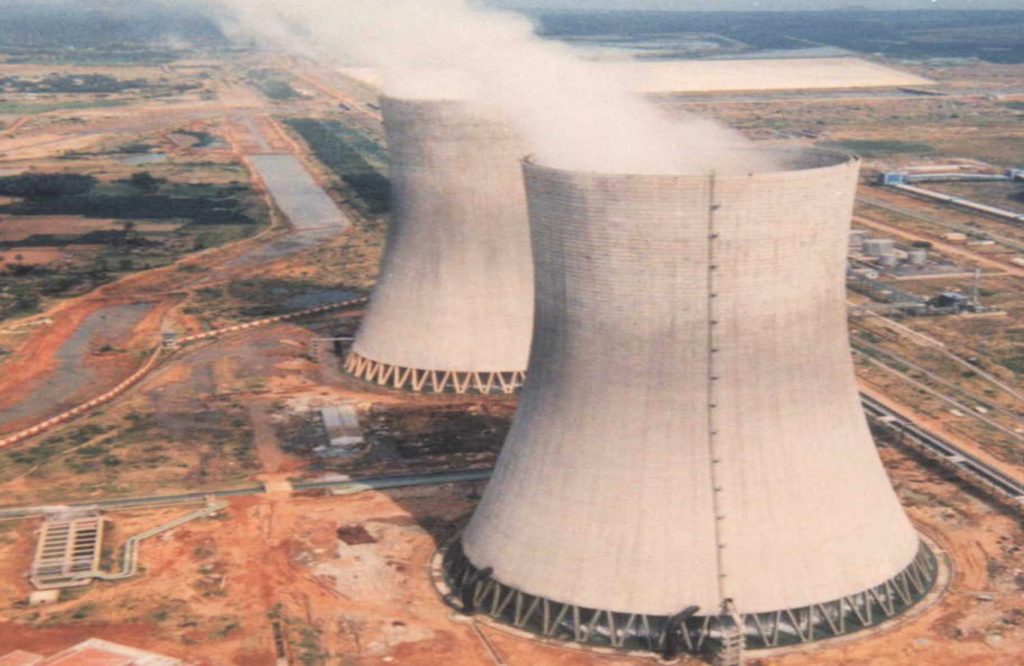

The power sector has also witnessed a massive change and emphasis is laid to commission several new thermal, hydel and atomic power plants in the coming years thus corrosion of steel and concrete has also become a serious concern for power plants especially in the splash zones areas and pipelines.

Ports and harbours also play a vital role in moving people and commerce, and the problem of corrosion is typically found on piers and docks, bulk-heads and retaining walls, mooring structures and navigational aids. There is no formal tracking of corrosion costs for these structures as of now. There is a need for holistic study on corrosion pertaining to the waterways and ports. Corrosion is also a major problem in shipping industry, particularly due to highly corrosive seawater and associated macro and micro organisms in the sea.

To sum up we can say that Corrosion poses one of the greatest threats to the efficient operation of Industries and Infrastructure. If not properly combated, it results heavy losses due to the shutdown of vital processes, the replacement of valuable equipment facilities and environment contamination.

Different methods to combat corrosion

There are various methods by which corrosion of steel can be prevented which include:

• Improving the quality of iron by alloying.

• Galvanising of steel

• Painting of steel rebar with epoxy or polymer coating systems.

• Coating of rebar with fusion bonded epoxy coating to avoid contact of metal with air and water.

• Use of migratory corrosion inhibitors for rebar corrosion protection.

• Surface coating on concrete and structural steel by using protective coating like epoxy, polyurethane or glass flake.

• Cathodic protection for pipeline corrosion protection.

• HDPE tapes for pipeline corrosion protection.

• Use of 100 per cent solid polyurethane coating system to protect concrete and steel surfaces.

STP combats corrosion

Construction chemicals maker STP offers advanced technology to encounter rebar corrosion and corrosion of concrete and structural steel.

• Use of ShaliPlast LW ++, migratory corrosion inhibitors for rebar corrosion protection.

• Use of ShaliUrethane PC, 100 per cent solid polyurethane coating system to protect concrete and steel surfaces.

ShaliPlast LW ++

The liquid organic migratory corrosion inhibitor to be added in small quantities to mixes of portland cement. There is little or no effect on the property of the concrete mix, including compressive strength, set time, air entrainment and workability. ShaliPlast LW ++ corrosion inhibitor when used in a repair mortar has the unique capability of diffusion and migration into the concrete and travelling some distance to protect the reinforcement present in concrete.

Surface coating

In order to protect concrete from the effects of environmental degradation various high performance coating are being used. There are several properties which a good coating should possess. These are:

• Good adhesion

• Flexibility

• Good mechanical properties

• Resistance to environment which may be chemical, moisture laden, sunlight, flowing water etc.

• Rains.

ShaliUrethane PC

The 100 per cent solid polyurethane lining for concrete and steel is a two-component elastomeric aromatic polyurethane coating. Conforms to ASTM D16 Type V classification. Solvent free, quick curing, heavy-duty urethane elastomer designed to provide exceptional protection for surfaces subject to movement or cracking in severe chemical and physical environments. Application areas include steel and concrete structures like cooling towers, containment areas tank, sea water intake pipelines, LPG mounded bullets and processing equipment, floor and deck coatings, sewage/waste water pipe lines, oil and gas pipelines, bridges and ships.

Authored by:

Sajal Mukherjee

President – Business Development Head Sales – North India

STP Limited

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.