Model 50 Concrete Block-Making Machine’s revolutionary features

By Edit Team | May 13, 2024 2:29 pm SHARE

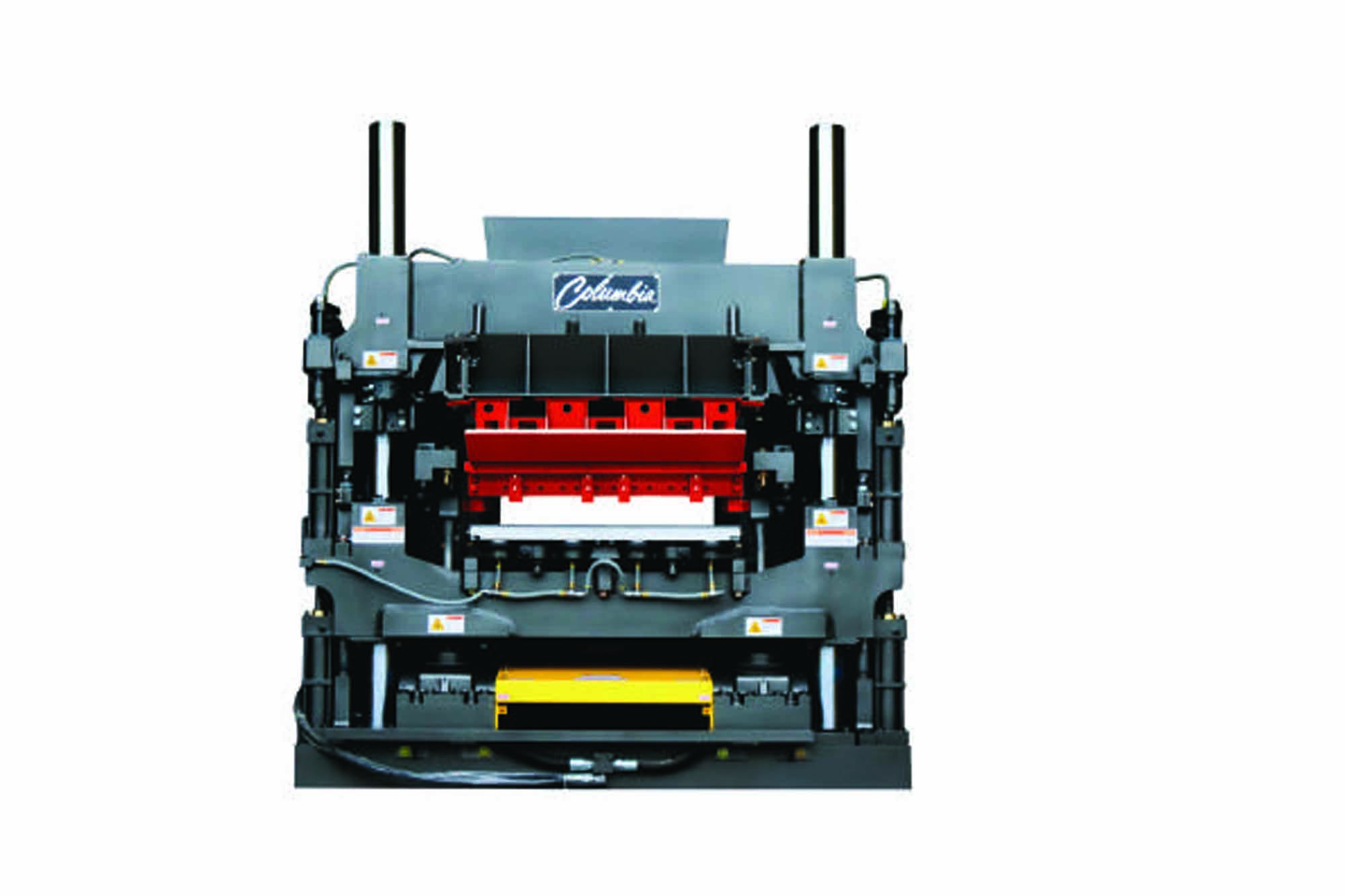

Innovation knows no limits, and the Model 50 Concrete Block-Making Machine by Columbia Machine Engineering exemplifies this truth. With its groundbreaking features and unmatched capabilities, this machine transcends traditional boundaries, redefining the landscape of concrete block manufacturing.

In the fast-paced world of construction and infrastructure, innovative technologies are constantly evolving to streamline processes, increase efficiency, and enhance the overall quality of building materials. One such groundbreaking product is the Model 50 Concrete Block-Making Machine by Columbia Machine Engineering. This cutting-edge machine has revolutionised the concrete block manufacturing industry, offering various benefits catering to large-scale projects.

The Model 50 is a state-of-the-art concrete block-making machine designed to produce high-quality, durable concrete blocks for various construction applications. Columbia Machine Engineering, a world leader in manufacturing construction equipment, has engineered this machine to meet the ever-growing & large-scale demands of the industry.

Key features and capabilities

Automated operation: Model-50 operates with an advanced automated system, such as an Automatic Rack and Pallet Handling System and Automated Product Cubing, reducing the need for extensive manual labour and minimising the chances of human error. This enhances efficiency and ensures consistent output and uniformity in block dimensions.

Versatile block production: Whether it is masonry concrete blocks, interlocking paver blocks, retaining wall blocks, bricks or paving stones, the Model 50 can manufacture various block types, catering to diverse construction requirements. This adaptability allows construction companies to diversify their product offerings and explore new business opportunities.

Precise molding technology: The machine incorporates precision moulding technology, ensuring that each block is accurately shaped and has a smooth surface finish. The Model-50’s meticulous moulding process results in sturdy blocks that fit together seamlessly during construction, enhancing the structural integrity of buildings.

User-friendly interface: Columbia Machine Engineering has engineered the Model-50 with a user-friendly interface, making it easy for operators to navigate and control the machine. The intuitive design allows even inexperienced workers to operate the machine effectively, reducing the need for specialised training.

High production capacity: The Model-50 boasts an impressive production capacity, capable of churning out a substantial number of blocks within a short period. This capability significantly accelerates the construction timeline, helping builders complete projects faster and more efficiently.

Advantages of the Model-50

Cost-effective: By automating the block-making process and reducing the dependency on manual labour, the Model 50 helps construction companies save on labour costs, making it a cost-effective investment in the long run.

Enhanced productivity: With its high production capacity and efficient operation, the Model 50 maximises productivity on construction sites. This, in turn, increases the overall output of projects and contributes to higher profitability for construction firms.

Superior block quality: The precise moulding technology ensures that the blocks produced by the Model 50 are of superior quality, exhibiting high strength and durability. This, in turn, leads to structures that can withstand the test of time and harsh environmental conditions.

Environmentally friendly: The Model 50 minimises material wastage and reduces the carbon footprint associated with concrete block production. The efficient use of resources aligns with sustainable construction practices, making it an eco-friendly choice for environmentally conscious builders.

Conclusion: The Model 50 Concrete Block Making Machine by Columbia Machine has undoubtedly transformed the construction industry with its cutting-edge technology and remarkable features. From improving productivity and reducing labor costs to delivering high-quality blocks, this machine has proven to be a game-changer for construction companies worldwide.

As the demand for sustainable, efficient, and innovative construction methods grows, the Model 50 remains at the forefront of this transformative industry.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)