Pumped concrete may be defined as concrete that is conveyed under pressure through either rigid pipe or flexible hose and discharged directly into the desired location. Pumping may be used for most of the construction but is especially useful where space or access for construction equipment is limited.

This article takes a comprehensive look at the simple method of concrete mix design for pumpable concrete. It is based on an estimated weight of the concrete per unit volume. The tables and figures included are worked out from various BIS codes and hand books by the author from a wide range of materials available in the country.

Pumping equipment consists of pumps, which are of three types:

- Piston type concrete pump

- Pneumatic type concrete pump

- Squeeze pressure type concrete pump

Other accessories are rigid pipelines, flexible hose and couplings etc.

A pumpable concrete, like conventional concrete mixes, requires good quality control, i.e. properly graded uniform aggregates, materials uniformly and consistently batched and mixed thoroughly. Depending on the equipment, pumping rates may vary from 8 to 130 m3 of concrete per hour. Effective pumping range varies from 90 to 300 meters horizontally, or 30 to 100 meters vertically. Cases have been documented in which concrete has successfully been pumped horizontally upto 800 meters and 400 meters vertically upward. New record values continued to be reported.

Pumping

For the successful pumping of concrete through a pipeline, it is essential that the pressure in the pipeline is transmitted through the concrete via the water in the mix and not via the aggregate; in effect, this ensures the pipeline is lubricated. If the pressure is applied via the aggregate, it is highly likely that the aggregate particles will compact together and against the inside surface of the pipe to form a blockage; the force required to move concrete under these conditions is several hundred times that required for a well-lubricated mix.

If, however, the pressure is to be applied via the water, then it is important that the water is not blown through the solid constituents of the mix; experience shows that water is relatively easily pushed through particles larger than about 600 microns in diameter and is substantially held by particles smaller than this.

In the same way, the mixture of cement, water and fine aggregate particles should not be blown through the voids in the coarse aggregate. This can be achieved by ensuring that the aggregate grading does not have a complete absence of material in two consecutive sieve sizes – for example, between 10 mm and 2.36 mm. In effect, any size of the particle must act as a filter to prevent excessive movement of the next smaller size of the material.

Basic Considerations

Cement Content

Concretes without admixtures and of high cement content, (over about 460 kg/m3) are liable to prove difficult to pump, because of high friction between the concrete and the pipeline. Cement contents below 270 to 320 kg/m3 depending upon the proportion of the aggregate may also prove difficult to pump because of segregation within the pipeline.

Workability of pumped concrete

The workability of pumped concrete, in general, has an average slump of between 50 mm and 100 mm. A concrete of less than 50 mm slump is impractical for pumping, and slump above 125 mm should be avoided. In mixtures with a high slump, the aggregate will segregate from the mortar and paste and cause choking.

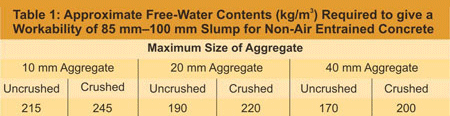

The mixing water requirements vary for different maximum sizes and type of aggregates. The approximate quantity of water for a slump of 85 mm and 100 mm is given in Table 1.

In high strength concrete due to lower water/cement ratio and high cement content, workability is reduced with the given quantity of water per cu.m. of concrete. In such cases, water reducing admixtures are useful. In the addition to this type of admixtures at normal dosage levels, to obtain higher workability for a given concrete mix, there is no necessity to make any alteration to the mix design from that produced for the concrete of the initial lower slump. There is generally no loss of cohesion or excess bleeding even when the hydroxylic acid-based materials are used.

If this class of product is used to decrease the water/cement ratio, again no change in mix design will be required, although small alterations in plastic and hardened density will be apparent and should be used in yield calculations.

A loss of slump during pumping is normal and should be taken into consideration when proportioning the concrete mixes. A slump loss of 25 mm per 300 meters of pipeline length is not unusual, the amount depending upon ambient temperature, length of the line, the pressure used to move the concrete, moisture content of aggregates at the time of mixing, truck-haulage distance, whether the mix is kept agitated during haulage etc. The loss is greater for hose than for pipe and is sometimes as high as 20 mm per 30 meter.

Aggregates

The maximum size of crushed aggregate is limited to one-third of the smallest inside diameter of the hose or pipe based on simple geometry of cubical shape aggregates. For uncrushed (rounded) aggregates, the maximum size should be limited to 40% of the pipe or hose diameter.

The shape of the coarse aggregate, whether crushed or uncrushed has an influence on the mix proportions, although both shapes can be pumped satisfactorily. The crushed pieces have a larger surface area per unit volume as compared to uncrushed pieces and thus require relatively more mortar to coat the surface. Coarse aggregate of a very bad particle shape should be avoided. The gradation of coarse aggregate plays an important part.

Difficulties with pump have often been experienced when too large a proportion of coarse aggregate is used in an attempt to achieve economy by reducing the amount of cement; such mixes are also harsh and costly to finish. The grading of coarse aggregate should be as per IS: 383-1970. If they are nominal single sized then 10 mm and 20 mm shall be combined in the ratio of 1:2 to get a 20 mm graded coarse aggregate. In the same way, 10 mm, 20 mm and 40 mm aggregates shall be combined in the ratio of 1:1.5:3 to get a 40 mm graded coarse aggregate.

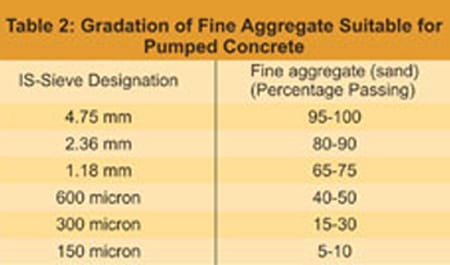

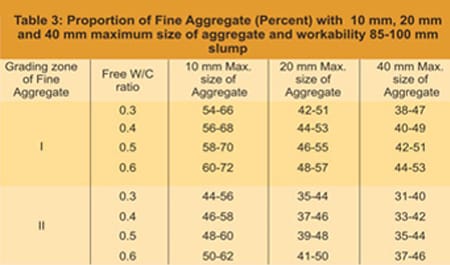

A fine aggregate of Zone II as per IS: 383-1970 is generally suitable for pumped concrete provided 15 to 30% sand should pass the 300 micron sieve and 5 to 10 per cent should pass the 150 micron sieve. A fine aggregate of grading as given in Table 2 is best for pumped concrete. The proportion of fine aggregate (sand) to be taken in the mix design is given in Table 3. However, the lowest practical sand content should be established by actual trial mixes and performance runs.

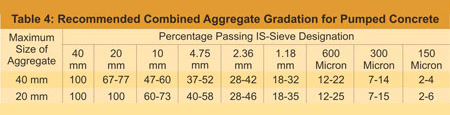

In practice, it is difficult to get fine and coarse aggregates of a particular grading. In the absence of fine aggregate of required grading they should be blended with selected sands to produce desired grading, and then combined with coarse aggregates to get a typed grading as per Table 4.

Uncrushed Aggregate (River Gravel)

It has become a custom that almost in all the construction sites crushed aggregates are being used. To save environmental pollution as far as possible in ordinary construction works uncrushed aggregates (River Gravel) if available as a local source including river sand should be used.

Production of crushed aggregates from crushers poses air and noise pollution problems.

Crusher & Air Pollution Problem

When the rocks and river bed boulders are crushed, dry surfaces are exposed and air borne dust can be created. An inventory of sources of dust emissions usually begins with the first crusher and continues with the conveyor transfer points to and including the succeeding crushers. Here the aggregate is more finely grounded, and dust emissions become greater. As the process continues, dust emissions are again prevalent from sources at conveyor transfer points and the final screens.

In the modern screening and washing plant in the production of uncrushed (gravel/shingle) aggregate from the river bed they are not crushed, thus no dust is formed. Further aggregates are washed to remove silt and clay like materials. Therefore, uncrushed (gravel/shingle) aggregates produces in these plants arrive at site in a moist condition, hence do not present a dust problem. Whereas the crushed aggregate leaves crushing plant very dry and create considerable dust when handled. To prevent dust in handling it is not possible to wet each load of crushed aggregate thoroughly before it is dumped from the delivery truck. Attempts to spray the crushed aggregate as it is being dumped have had very limited effectiveness.

During crushing of aggregate particles, less than 100 micron remains suspended in the air. The suspension of a particle in the air follows a certain trajectory depending on its size, density, shape and other physical properties. In air turbulence, the dry crusher dust has long trajectories or suspension time and settling distance to the ground. If a crushing plant is not properly designed and operate without any efficient prevention system this “fugitive” dust may generate air pollution.

Air quality due to pollution should be monitored monthly.

Pumping

Before the pumping of the concrete is started, the pipeline should be primed by pumping a batch of mortar through the line to lubricate it. A rule of thumb is to pump 25 litres of mortar for each 15-meter length of 100 mm diameter hose, using smaller amounts for smaller sizes of hose or pipe. Dump concrete into the pump-loading chamber, pump at slow speed until concrete comes out at the end of the discharge hose, and then speed up to normal pumping speed. Once pumping has started, it should not be interrupted (if at all possible) as concrete standing idle in the line is liable to cause a plug. Of greater importance is to always ensure some concrete in the pump receiving hopper at all times during operation, which makes necessary the careful dispatching and spacing of ready-mix truck.

Testing for Pumpability: There is no recognized laboratory apparatus or precise piece of equipment available to test the pumpability of a mix in the laboratory. The pumpability of the mix, therefore, should be checked under field conditions.

Field Practices: The pump should be as near the placing area as practicable and the entire surrounding area must have adequate bearing strength to support the concrete delivery trucks, thus assuring a continuous supply of concrete. Lines from the pump to the placing area should be laid out with a minimum of bends. For large placing areas, alternate lines should be installed for rapid connection when required.

When pumping downward 15 m or more, it is desirable to provide an air release valve at the middle of the top bend to prevent vacuum or air buildup. When pumping upward, it is desirable to have a valve near the pump to prevent the reverse flow of concrete during the fitting of clean up equipment.

Conclusion:

Pumped concrete is common now for almost all constructions requiring a large volume of concrete to be poured. It is extremely useful for highrise buildings, industrial structures like TG Foundations requiring an uninterrupted large volume of concrete to be poured.

Although the ingredients of mixes placed by the pump are the same as those placed by other methods, quality control, batching, mixing, equipment and the skill set of personnel with knowledge and experience are essential for successful pumped concrete.

The properties of the fine normal weight aggregates (sand) play a more prominent role in the proportioning of pumpable mixes than do those of the coarse aggregates. Sands having a fineness modulus between 2.4 and 3.0 are generally satisfactory provided that the percentage passing the 300 and 150-micron sieves meet the previously stated requirements. Zone-II sand as per IS: 383-1970 meets these requirements, and is suitable for pumped concrete

Authored by:

Saibal Kumar Roy,

Sr. VP Engineering,

REPL (Rudrabhishek Enterprises Ltd)

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.