This case study highlights the challenges dealt with while treating Maharashtra sewage treatment plant with STP.

Background

A residential complex in Maharashtra has a sewage treatment plant of 140 KLD. The plant receives an average flow of 3 KL per day from the canteen (dish washing water) and the toilets. Major portion of the sewage being urine resulted in a yellowish orange color and pungent odor. The detergents and surfactants from toilet and canteen cleaning resulted in foaming issues at the plant.

Major Challenges:

- Fully operational STP with low availability of sewage

- Low organic load leading to low maintenance of MLSS

- Odour Control • Meeting PCB discharge norms

Situation Analysis:

Two major problems affecting overall system performance were

Nutrient Scarcity:Like human beings, bacteria need food to survive. Lack of availability of food within the biological system was hindering the growth and development of microbes. As a consequence, desired MLSS level was not achieved and maintained.

pH: PH plays a pivotal role in growth and development of bacteria and other life forms present in the sewage. Microbes grow optimally at neutral pH (pH 7). The raw sewage had a pH of 9 – 10, which was again hindering biomass development. Therefore, addition of citrate was suggested to lower the pH, as unlike other acids, citrate does not affect microbial growth and multiplication rather it boosts their growth by acting as a carbon source in the medium.

CleanMaxx + Microbster’ – the economical biotech solution Since several decades, biological treatment has proven to be an eco friendly and economical approach to degrade variety of organic pollutants. But the efficiency of this treatment majorly depends upon the beneficial microbes present in the system.

CleanMaxx STP – a consortium of beneficial microbes – has superior strains of non- genetically engineered and robust microbes rather than a single strain, thereby making it more suitable for surviving under varied temperature and fluctuating organic load. This helps in faster commissioning of biological systems. The microbes are micro- encapsulated to provide better shelf life. “Microbster” is a powerful nutrient enriched UREA-DAP replacement. This is especially formulated to boost microbial development under stringent conditions. It requires only 1/4th the dosing of UREA-DAP

Approach:

- The aeration tank was completely filled with 40kl of raw sewage

- Recommended quantity of “CleanMaxx” and “Microbster” was added to the aeration tank

- Minimal dosage of citrate was added to neutralise pH

- The system was provided aeration on continuous basis

- Microscopic analysis was carried out at intervals to monitor the microbial activity

- Lab analysis was conducted after start of the treatment

Lab analysis reports after start of treatment:

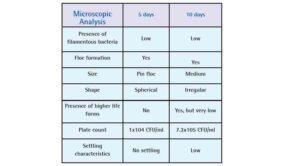

“Biocheck”1 study on the aeration tank sample was carried out on regular basis at our in-house R&D facility.

Analysis Report after “CleanMaxx” and “Microbster” addition:

Results:

MLSS Development: MLSS analysis was carried out on a regular basis along with COD and BOD analysis to check the development of biomass. The implementation team observed significant improvement in terms of growth within 15 days from the time of commissioning. On the 15th day of the study, MLSS was found to be in the range of 1000-1200 mg/lt. By the end of the project, desired MLSS 2000-3000 mg/litre and MLVSS of 1500-2000 mg/ litre were achieved. This shows that the ratio of MLVSS: MLSS was 0.66, which indicates the optimum desired parameter.

Odour Removal: Our microbial technology comprises of several effective strains that do not cause putrefaction during the degradation process. Also these microbes enhance the rate at which ammonia is converted into nitrite and subsequently into nitrate, eliminating the release of ammonia gas. Significant reduction in odour was noticed within 7 days and odour was completely eliminated within 15 days of “CleanMaxx STP addition.

Conclusion:

- The biological system of STP was successfully commissioned within 30 days of start of “CleanMaxx” and “Microbster” addition.

- 100% foaming and odour eliminated.

- Desired biomass levels for proper functioning of the biological system was achieved and was maintained consistently.

- Average COD and BOD levels of the treated sewage was below 55 ppm and 7 ppm respectively, which are within the PCB prescribed limits.

Expertise shared by: Priyanka Khaire, Sr. Executive Wastewater & Bioremediation, organica biotech Pvt. Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.