Spartan Engineering’s cutting-edge innovations are transforming the construction sector

By Edit Team | July 17, 2023 2:46 pm SHARE

Spartan’s state-of-the-art production facility in Nashik stands tall as a world-class infrastructure solutions provider.

Spartan Engineering proudly reflects on its journey of five decades, attributing customers’ sustained and enthusiastic show of appreciation since its inception in 1971 to its unwavering ability to unlearn, relearn, upgrade, and evolve. Over five decades, the company has remained true to the Spartan legacy, embodying the spirit of fighters who passionately pursue perfection in everything they do. This pursuit has created exciting stories of reliability and trust, marking significant milestones along the way. According to Spartan, achieving Excellence is not a finite destination but an ongoing process that continually enhances their product, service, quality, and relationship paradigm. They aim to go beyond their client’s expectations and bring an additional smile to their faces through their deliveries.

Spartan’s growth story is highlighted by the satisfaction of more than 4,000 customers. The quality of a country’s infrastructure, education standards, and medical ecosystem defines its development index, with infrastructure playing a vital role in strengthening these metrics and improving the user experience.

Bhiwandi Factory

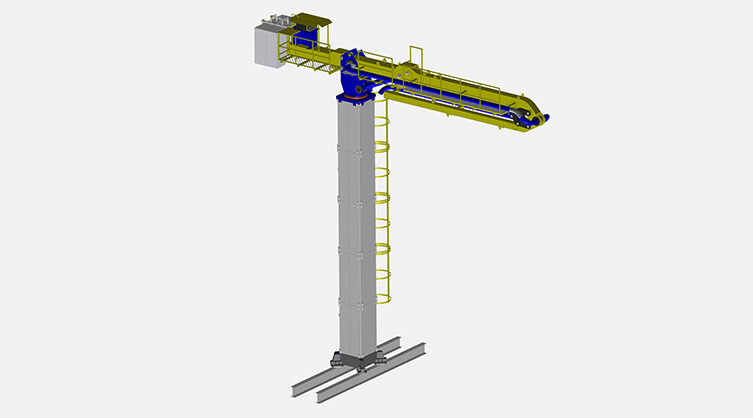

Spartan Engineering takes pride in its journey of five decades, which has significantly contributed to India’s growth story through innovative advancements in high-end construction equipment. As an ISO 9001:2015 certified manufacturer and supplier, Spartan specialises in producing bar bending machines, bar cutting machines, passenger and material hoists, multi-functional material hoists, rope suspended platforms and lift shafts, stirrup bending machines, spiral bending machines, firemen evacuation lifts, and concrete placer booms.

Many landmark infrastructural projects, including commercial and residential buildings, roads, highways, bridges, flyovers, dams, and tunnels, are testimonials of Spartan’s dedicated efforts.

Dr. Vikram Mehta,Managing Director

Dr. Vikram Mehta,Managing Director

Dr. Vikram Mehta, the Managing Director, is a proficient representative of the dynamic second generation that successfully transformed an engineering operation into a new-age, technology-centric construction equipment manufacturing company. Today, Spartan Engineering is renowned for its next-level multi-functional material hoists and groundbreaking innovations in construction equipment. Dr. Mehta’s exceptional work has been acknowledged through numerous prestigious awards, including the Maharashtra Saavali Puraskar Award presented by Mr. Bhagat Singh Koshiyari, the Maharashtra Governor, Entrepreneur of the Year by ET Ascent, 2022 MD of the Year, India’s Inspirational Leader by WCRC Leaders, Innovative Product Design Award, and many others. These awards were bestowed in recognition of his proficiency in entrepreneurship, leadership, innovation, and remarkable accomplishments in the industry.

Passenger and Material Hoist

Production of more than 7000 machines on site every year

The company’s visionary approach, as exemplified by Dr. Vikram Mehta, has led to the establishment of manufacturing plants at Kalwa and Atgaon that redefine the “state-of-the-art” infrastructure concept. These plants, equipped with advanced machinery and meticulous adherence to systems and processes, are pivotal in producing revolutionary bar bending and cutting machines, essential in India’s landmark infrastructural projects. The integrated facility encompasses various functions, including fabrication, production, assembly, testing, design and development, spares management, and dispatch. Supported by a strong research and development department, a nationwide presence, and adherence to QMS 5S, and C Certification, Spartan Engineering emerges as a truly world-class provider of infrastructure solutions.

The projection for 2026: lending structure to infrastructure

It was projected that in 2026, Spartan Engineering would lend structure to the infrastructure. The Spartan growth story was spearheaded by a lavish 3500 sq. ft. corporate office in the busy commercial district of suburban Mumbai. Furthermore, dynamic office spaces in Dubai, Brazil, and Colombo would empower their global operations, enabling them to secure a prominent market share in 10 countries. Alongside this international presence, they aimed to maintain a nationwide footprint across 30 cities, capturing a 10 percent market share in the fire lifts manufacturing segment.

Bar Bending Machine

Upgrading the quality quotient in the industry

Spartan emphasised its dedication to upgrading the quality quotient in the industry. They expressed their passion for perfection, which motivated their research and development efforts to enhance their products. Manufacturing plants in Atgaon and Kalwa were committed to producing CE-certified products that adhered to European safety and quality standards, thus contributing to the elevation of the industry’s quality standards.

Certifications: Spartan Engineering adheres to stringent specifications in three key areas: Quality, Safety, and Environment, gaining global recognition as a trustworthy brand. Its certifications testify to its commitment: ISO 9001:2015, CE, OHSAS 18001:2007, and Environmental Certificate.

Bar Cutting Machine

Research & design team with advanced technology & software:

Spartan’s dedicated Design & Development team consists of 16+ professionals with expertise in engineering design & development. We conduct exhaustive research to design fire-rated wall panels and other static and dynamic parts of the Fire evacuation device, following globally accepted standards. SolidWorks is used for 3D solid model design, static and dynamic analysis (FEA) of machine components, and documentation, ensuring strength and reliability.

Concrete Placer Boom

Spartan Rope Suspended Platform

Service engineers are always close to customers:

We have secured a well-trained team of technicians with 10-20 years of hands-on experience with leading construction companies. Experts from mechanical and electrical backgrounds are available 24/7 at each location to serve our customers. We also provide training on the safe usage and maintenance of machines through our in-house training facility. We are equipped with an ERP-backed Call Management System App and dedicated service coordinators at national and regional levels, ensuring a timely response to customer calls.

Fire Evacuation Lift

Spartan Fire Evacuation Solutions:

Rescue up to 20 people simultaneously, 90 percent faster. 99 percent safer than alternatives. Features include 2-way communication, 2-hour fire-rated body panels, four power backups, inbuilt AI-IoT, and 100+ quality checks—customisable to specific needs, minimising firefighter fatigue.

For more information, visit: https://spartanindia.com/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.

-20240213125207.png)