Everything has its pros n’ cons. But the question arises here is who stands best between Concrete Slabs and Pavers? Have a look at what the experts has to say on this.

Concrete slabs are often used for outer areas as pavers

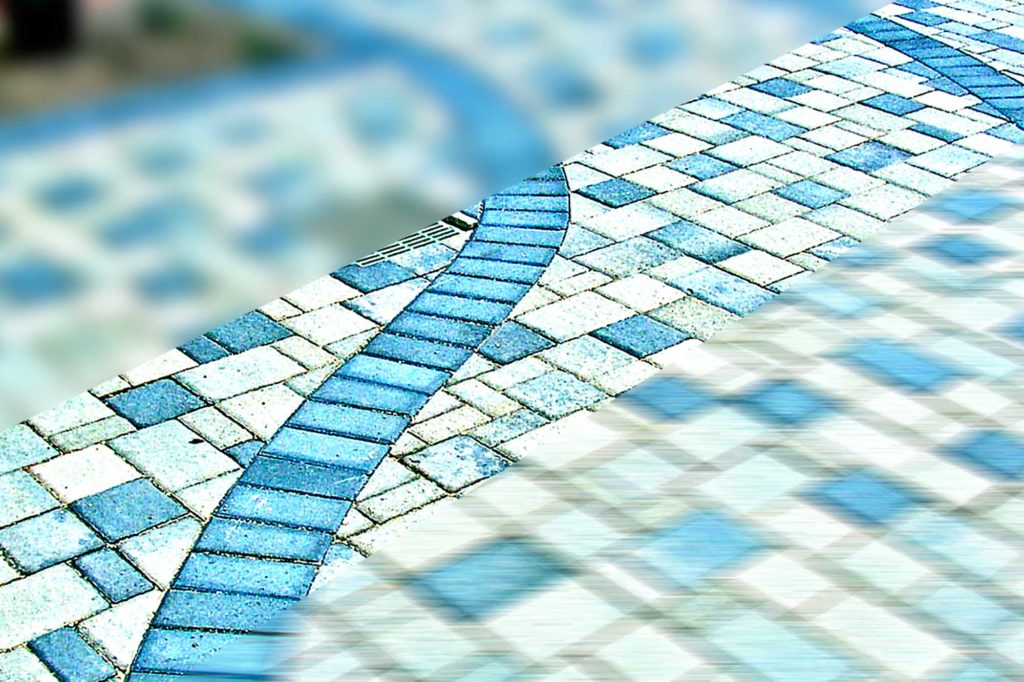

Nowadays paving is a trend established in all outer areas of residential commercial and institutional buildings. Usually, concrete slabs are often used for outer areas as pavers due to various factors.

“Developments are taking place and of options are available for pavements like stamped concrete, colourful interlocking pavers with having options of design and textures. Pavements are made of individual sections like natural stone concrete or bricks many of these pieces interlock which make for a flexible system that is extremely durable,” says Girish Bothra, Managing Director, Reackon Concretes Pvt Ltd.

Cost comparison of concrete slab and pavers

Girish opines, “Standard concrete slabs seem to be lower in cost per Sq. feet than other alternatives of pavements but concrete slab is costlier around 25 per cent than alternative paving materials.”

Concrete slabs are not affordable because of long term cost for repair and changes in behaviour of concrete due to variation in temp like cracking etc. He informs, “The placing of concrete slab can be executed in a day but finishing will not be executed within a day, i.e. trimix and cutting of concrete too. Concrete pavements are disallowing to percolate or seepage of water in ground which also affects the Green environment.”

Installation

Girish believes that concrete slab are somewhat easy to install but material takes time to cure the installation (excavation, laying, grading, prep for foundation, setting forms and pouring) in due course of time formation of cracks in concrete is a routine process. It is very important to maintain proper grading (slopes) at the time of laying due to any error if it is not maintained then it leads to low spots where water retains and looks very shabby.

In case of installation of pavers, Girish feels that pavers are easy to install because of those are manufactured under precision available in various designs with lots of textures, requires proper prep of base compaction to maintain gradation. He observes, “As there is no requirement of curing its ready to use immediately after completion if anything goes wrong in grading pavers can be easily to correct the issue by removing regarding the problematic area and replacing them.”

Maintenance

Concrete is relatively difficult to maintain because of its behaviour during variation in temperature i.e. Cracking and chipping due to abrasion or impact. He claims, this ultimately results into disturbance of entire concrete slab. Whereas, pavers are easy to maintain and if anything goes wrong, we can easily remove and replace them.

Durability

Concrete slabs in longitivity are greatly affected due to movement of the earth slabs are prone to splitting and cracking if the ground below it shifts. Changes in temperature cause expansion and contraction in concrete which also results in cracking. Due to disturbance in gradation, there is a scope to settle water on surface which may cause accidents, Girsih informs.

He said, “Pavers are rated to be stronger with a guarantee against breaking and cracking. Pavers stand up very well to changes in weather conditions and their ability to expand and contract without cracking.

Safety and Value

Concrete slabs can often be very slippery when wet which can cause cars lose traction and leave tire marks on a newly installed concrete driveway. Additionally, a slippery pool deck or patio can be very dangerous if someone were to fall on the hard concrete deck.

“Pavers are manufactured to be non-skid and non-slip. This means vehicles will always have traction, which will help prevent tire marks and adults and kids will never slip on a wet pool deck or patio,” adds Girish.

In terms of value, pavers are considered to be one of the only hardscape products that instantly add value to your home upon installation.

Due to their versatility, aesthetic and lifetime product guarantee, pavers are quickly becoming the preferred hardscape solution among homeowners and contractors,” concludes Girish.

“Manufacturing of decorative concrete slabs is a modern concept of making products of bigger dimensions when compared to traditional pavers, and they are currently popular,” says Jayaram Ramesh, Managing Director, Sri Parijatha Machinery Works Pvt Ltd.

Trend for large format slabs

“Interlocking pavers are of the traditional concept, which is still popular; however, manufacture of bigger slabs is getting popular and used more widely nowadays. Pavers are used for pavements whereas concrete slabs can also be used as drain covers, due their bigger size,” claims Jayaram.

Both pavers and concrete slabs can be made on different types of machines like wet cast, hermetic press, and vibro press. Parijatha is a company which provides all these machines, with an end-to-end solution and also a linear wet press with which, very high density slabs and kerbs can be manufactured.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.