Vasim Pradhan, Head of Sales at Ashar Locker, discusses the company’s high-performance and sustainable screening materials achieved through ISO standards, ethical sourcing, and innovation.

How does Ashar Locker ensure high-performance and durable screening materials?

The company adheres to the latest ISO quality standards for consistent product quality and customer satisfaction. Wires are procured from reputable manufacturers like Tata Steel Ltd. or equivalent suppliers worldwide. Their R&D team formulates the right chemical composition for wire efficiency. Wires are made to their specifications by vendors. Unlike local suppliers who often draw wires from scraps, Ashar Locker avoids compromising quality for cost.

They emphasise the significance of screening areas to enhance plant efficiency and lower costs. Customers can rely on Ashar Locker as a trustworthy and efficient screening partner.

What testing and evaluation processes does Ashar Locker use to assess screening materials?

We employ rigorous testing methods to ensure that our meshes are of the highest quality worldwide. Embracing Lean principles like First-In-First-Out (FIFO), PCDA, Just-in-Time (JIT), Standard Work, Poka-Yoke, and 5S, we optimise efficiency, reduce waste, and continuously improve our manufacturing processes. Our focus on innovation and technology has led to high demand for our products across all mineral industries. Our dedicated R&D team constantly works on developing valuable products for our customers.

What measures does Ashar Locker have in place to address the challenges of sourcing quality screening materials?

At Ashar Locker, we prioritise ethical and sustainable sourcing and production of our products. We carefully select suppliers who adhere to ethical practices and comply with labour and human rights standards. We ensure transparency in the supply chain and evaluate suppliers’ commitment to fair trade principles. We have implemented a “Safety First” culture at our factory, prioritising the well-being of our employees with strict safety protocols to create a secure work environment.

Additionally, our partnerships with ethical leaders like Valmont Group USA and Locker Group further reinforce our commitment to sustainability and responsible manufacturing. Ashar Locker actively engages in sustainability initiatives. By integrating ethical sourcing, sustainable manufacturing practises, safety measures, a lean culture, and continuous employee development, we strive to deliver products that meet the highest standards of quality, ethics, and environmental responsibility.

Which steps are taken to ensure environmentally sustainable screening materials?

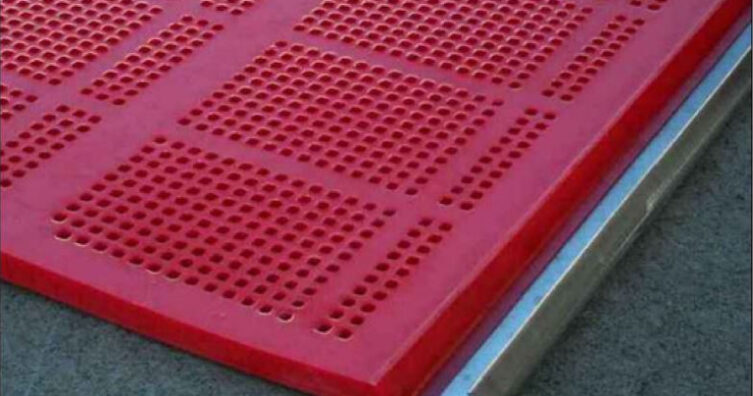

At Ashar Locker, we not only prioritise efficiency but also strive for environmental sustainability. For instance, some competitors use a toxic chemical called MOCA in manufacturing Poly-urethane panels to cut costs. However, this poses serious health risks to the people involved in the process, as well as to the customers who use such panels. Harmful emissions are released when these panels are exposed to sunlight. At Ashar Locker, we avoid using such materials that can be detrimental to our employees, customers, and the environment.

We strongly believe that it is not just our responsibility but also the responsibility of our customers to ask the right questions to their suppliers during the procurement stage. This way, they can ensure that harmful chemicals like MOCA are not being used in their products. By promoting environmentally sustainable practices, we hope to foster the growth of eco-friendly products in the market.

Can you please elaborate on the latest advancements in your screening products and materials? How are they impacting the screening processes?

As a company, we understand the significance of technological advancements and continuously seek opportunities to leverage them for improving our operations and services. Our future strategies are centred around innovation, product development, and enhancing our digital capabilities to enhance the customer experience. We firmly believe that staying at the forefront of technology will drive long-term growth and success.

Our anti-clogging screens at Ashar Locker have proven to be exceptionally successful in the production of M-sand and P-sand over the last few years. These screens are meticulously handcrafted and designed to utilise every motion efficiently. Each wire vibrates independently, resulting in improved plant efficiency and precise cuts for sand manufacturing.

In comparison to wire meshes, our Rubber and PU meshes offer superior wear life, generate less dust, produce minimal sound pollution, and boast increased durability. However, the only trade-off is a reduction in open screening areas. We provide expert guidance to customers on choosing the right combination of meshes to maximise their plant’s value. For instance, non-metallic and metallic meshes serve different purposes and can be strategically installed, like a non-metallic top deck, a metallic second layer, and an anti-clogging screen on the third level.

Overall, these advancements have significantly improved the screening processes and contributed to the overall efficiency and effectiveness of our screening products.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.