Henkel adhesive solutions for moulded and flush doors are user friendly and convenient to apply to the surface and easy to clean

Moulded panel doors are the prefabricated doors. These doors may be fabricated to fit various applications and operational requirements. Their design structure usually varies with the application area and might use several different materials.

Depending on the application area, superior quality adhesives have to be used to ensure optimal shelf life, and meet operational parameters.

Henkel’s AQUENCE brand has access to the full range of water-based technologies which includes:

• Water-based acrylic

• Water-based colloids and

• Water-based PU dispersions

• Water-based PVAC

• Water-based VAE dispersions.

AQUENCE solutions enable customers to improve their total cost of ownership and product quality for consumer products in various industries which includes construction, furniture and wood-working industry as well.

Henkel offers international grade adhesives for moulded panel & flush door, which are:

• AQUENCE MD 161 (meets EN 204/205 D2 standard)

• AQUENCE KL 472 FF (meets EN 204/205 D3 standard)

• AQUENCE SL 463 (meets EN 204/205 D4 standard).

Process

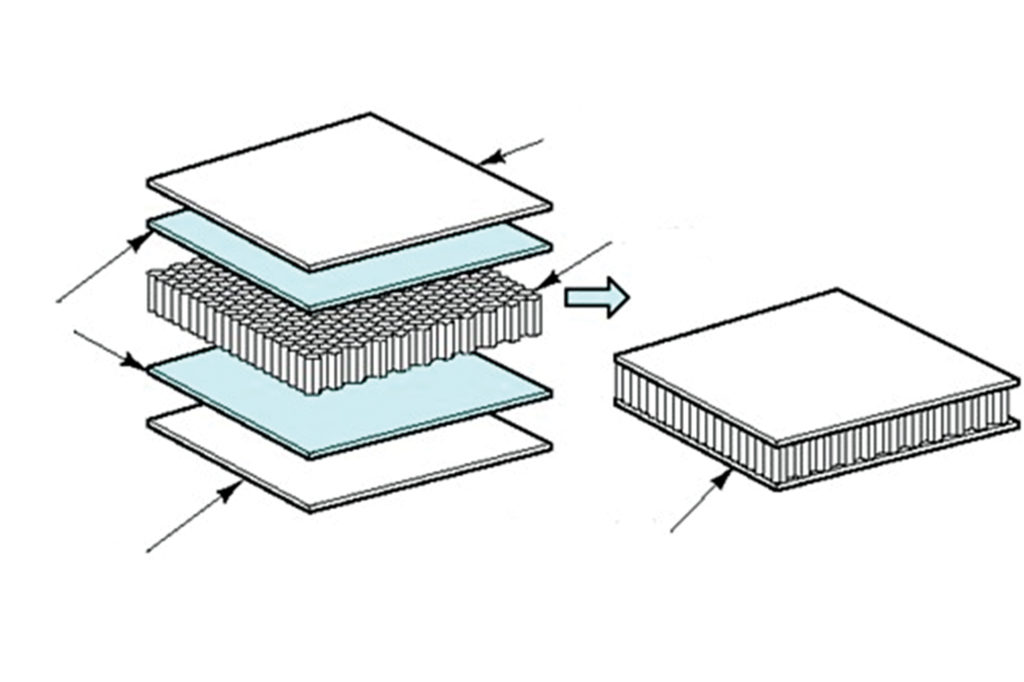

The door panels can be fabricated with a smooth or grained surface. The door panels are primed with a water based primer and anti-metal mark coating, after the pressing process. The anti metal mark coating is applied to keep the surface clean during the whole manufacturing process. The doors are then cut into required size. Independent door manufacturers then make interior Moulded doors from the door panels.

Features

• Henkel Adhesive solutions for moulded and flush doors are user friendly and convenient to apply to the surface and easy to clean

• Can be applied to the surface by spraying, brush as well as mechanical glue spreader

• Open time can be modified according to the application; so there can be provision for long or short open time

• Mono or two components, depending on the requirement

• These are D3 and D4 water resistant adhesive

• Adhesives maintain the dimensional stability – warping, twisting and cupping of the moulds

• No chance of blister formation and hence no rejection

• Solutions are environmental friendly, have no harmful emissions

• Adhesives are free from hazardous formaldehyde, are non toxic and non flammable

• Ideal for both cold and hot pressing

• The dried adhesive film is non brittle, with soft and resistant glue line.

• No worry if glue ooze out into surface, the adhesive doesn’t spoil the skin surface after curing

• It has a transparent adhesive film

• Henkel Adhesives save energy.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.