Everest Industries was founded to serve the construction equipment industry by providing products such as tower cranes, passenger hoists, and services to the real estate sector, cement plants, power plants, and steel plants. Over the last ten years, we have sold over 650 units in India.

Innovations to speed up construction projects

Passenger Hoists: Our new passenger hoist has a cage length of 3.6m to 4m and can transport 24 people or 2 tonnes of the load simultaneously with a speed of 63m/min. This length is in high demand in India since developers want to transport façades and door/window frames through the hoists. CNC high-speed stirrup bender: Our high-speed rebar processing machine is a CNC high-speed stirrup bender. We have two types available: one for up to 12 mm rebar and the other for up to 16 mm rebar. In India, mostly 12mm rebars are made; hence the former is more popular. But the 16mm rebar can process 2 rods simultaneously if the bars are 12 mm or below.

These machines are unsuitable for feeding straight-type rebars since one rod will be processed within 15 seconds. Coil-type rebar needs to be provided to the machines, and using coils is the best way because it helps reduce the wastage while feeding a single bar with 2500m to 3000m coils can be fed.

Maintaining steel tensile strength.

There is a massive variation in steel tensile strength and diameter of TMT rods obtained from local manufacturers in the Indian market. The European machines fail terribly in their operation while handling such raw materials. In contrast, our machines have been developed after two years of research and can easily handle such variations without failure.

Safety parameters of crane operations for tall buildings

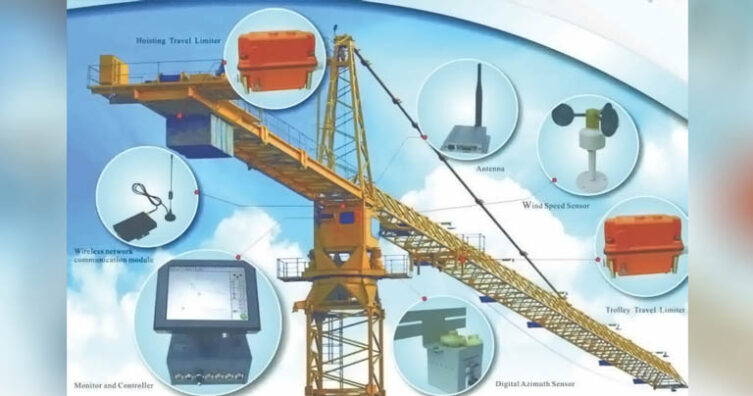

The government has made anti-collision systems mandatory wherever multiple tower cranes are used to avoid collisions with each other or with trees, buildings, and other tall objects. One of the disadvantages of the market system is that if one of the cranes loses power while working, it falls off the radar of the other cranes in the same area. This is risky because the powerless crane can move in any direction due to wind pressure, which the other cranes will not notice. Another important point I would like to highlight is the illegal frequencies used in the anti-collision systems market. These can be very dangerous since they interfere with various communication systems. Everest systems use only the 335 MHz band, which the Ministry approves of Communication for crane control (unlicensed). I think site engineers and developers should become conscious. Moreover, because of the price sensitivity of the buyers, we do not want to compromise on quality. And hence, our entire focus will be on increasing our products’ reliability, quality, power savings, and safety. At Everest, our in-house developed systems include a protection feature that alerts other cranes if any crane loses power while working and prevents them from entering the powerless crane’s operation circle.

Equipment manufacturing and imports

We are establishing our manufacturing plant in Mumbai, and production will begin in mid-2023. Our products will be sold under the EEE brand. Our straddle carriers and launchers are imported from China as there is no domestic production. However, most Chinese manufacturers provide lower-cost products that don’t meet the design standards or the necessary strength requirements, that’s why the customers are experiencing widespread beam deflection issues.

The key concern with these companies is that although they offer low-cost equipment, they fail to own and address the failures in this equipment. However, some excellent Chinese manufacturers, such as HCR, produce high-quality equipment. This Chinese government company does not use low-cost materials testing, welding, and other similar methods. In 2009, AFCONS and Navayuga Engineering purchased equipment from HCR, and the machines are still operational. We, at Everest also import from HCR to provide high-quality equipment to our Indian customers.

Equipment rental business

We entered the rental business in 2015, and in 2020, we established Everest Rentals. We have rented 25–30 machines, including passenger hoists and mast climbers. We also provide anti-collision systems to some businesses for projects lasting 5 to 6 months. We do not intend to rent tower cranes, but we may consider renting out our rebar processing machines in the future.

Business expansion plans and exports

These days, buildings are being made up to 400m high, but the locally manufactured equipment can go up to 150m. Our standard passenger hoists will be able to reach 500 m, and they will have a life of 20 years. At our R&D centre, we will make products as per international quality standards. We will develop, document, and do stringent quality control since we also plan to target the export market.

We intend to export only after establishing a solid brand in the Indian market. We surveyed to investigate the needs gap in the Indian market and the export opportunities. We are currently working on producing products that meet European standards, and we will begin exporting in a few years.

Our sales team is present all over India. We have recently expanded our dealer network to include Haryana, Punjab, and the Northeast. We can provide service to any machine in any part of India within 24 hours, and this service efficiency has been the sole reason behind our spectacular growth.

Furthermore, we conduct training camps every month for our customers and engineers. We are an ISO 9001: 2015 certified company by TUV. Our customers are expected to not only maintain the equipment but also maintain its documentation. Our engineers check this periodic maintenance documentation and cross-check it with the equipment. We train our staff and customers if the maintenance is not found satisfactory. We also maintain the highest safety standards on our equipment and services as per ISO-45000.

The domestic market is promising

The Indian construction equipment industry has grown by 25 per cent (excluding pandemic years), and we expect it to grow at a 25 per cent rate for the next ten years. Because of the pandemic, our turnover was reduced by 20 per cent in FY 2020–21, which had a fall-out effect in FY 2021–22. However, the market has recovered well, and we anticipate a 40 per cent increase in the coming fiscal year. So, overall, the market looks promising.

For more details, visit: www.everestengg.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.