We would like to show the top class production facility which gives the best quality, higher output and accuracy results in longer life for the machines.

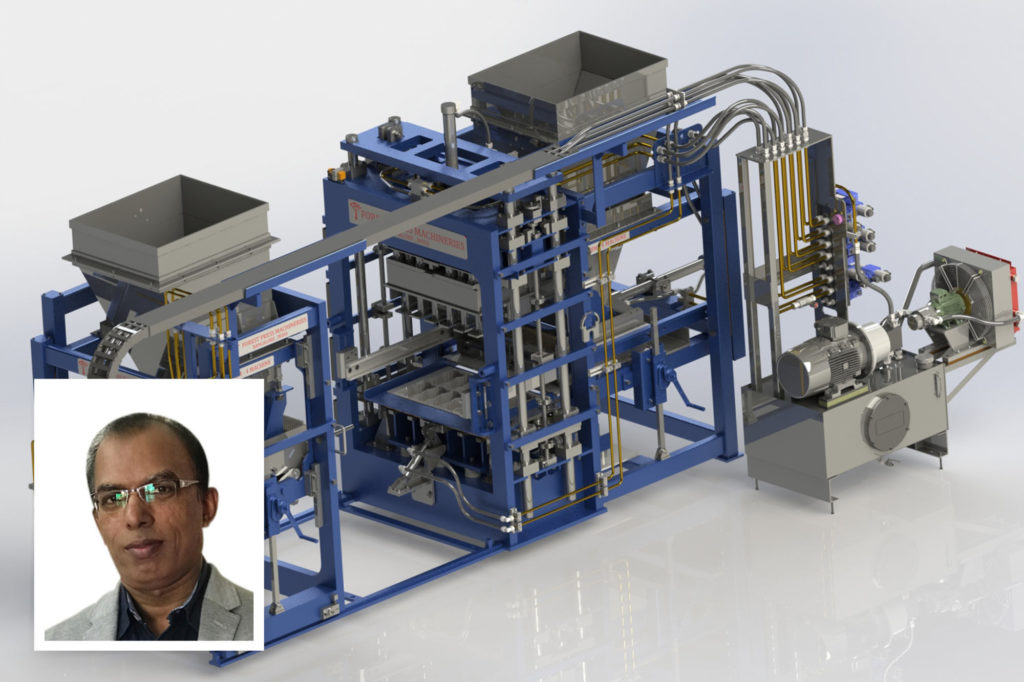

Manoj Pillai, Managing Director, Forest Press Machines

Forest Press Block Master Series of machine models is designed to produce blocks, pavers and fly ash bricks. The entry level model BM 4 is capable to produce 5,000 blocks, 17,500 pavers, 20,000 bricks per shift with 6 employees. The model BM 9 is able to produce 15,000 blocks, 50,000 pavers, 60000 bricks per shift. These machines are offered with standard as well as customised options suits to the project requirement.

Forest Wet Press such as mini press, single station, triple station and five station machines are well known for the production of high density kerb stones, slabs, flag tiles with various dimensions and finishes are available.

Forest Universal Tile Press with four stations in two layers is the new launch. The base with semi-dry concrete and top layer with wet and coloured concrete gives special products such as terrazzo tiles, chequered tiles and other products.

Mega Star Series of planetary mixers are starting with 375 litre and available with 500, 750, 1125 and 1500 litres with moisture probe, colour dosing, travel weigher and flying bucket transfer systems.

AAC plants in association with WKB Germany will be another highlight which is starting from 300 cbm to 1500 cbm per day. The cutting machines, tilting system and green separator from Germany and all other items from India helps to save the import duty, freight and cost savings.

Eco Filters from UK will show the best designs jointly with Forest Press during EXCON 2017. Eco filters are famous for the artificial and natural stone effects and images on concrete elements.

Why Forest Press Machines known for quality and design?

“Forest Press Machines designed with the latest technology are well-known for the quality. The machine parts are obtained from the global leaders which engineered and tested in house with dedicated team,” informs Manoj Pillai, Managing Director, Forest Press Machines. He adds, “By using the standard parts and adopt the plug-and-play solution gives us the flexibility and after sales service much better than any competitor worldwide. 24/7 service is available and the software is written in the latest Siemens S 1500 software in English language.”

Forest Press – A right choice

Quality in affordable price for the developing markets such as Asia, Middle East and Africa. These are the most price sensitive and premature markets which normally looking for cost-effective and simple solutions rather than the high-end complicated ones. Pillai says, “We are very much aware of the ground reality and launch the new machines suits to these markets. Service and parts are other important factors in so called markets and Forest Press is the right choice for it.”

New announcements

The new production facility for Forest Press Machines in India is getting ready which is expected to inaugurate by March or April 2018. This covers a production area of 60000 sq. ft. with 6 cranes and robotic welding as well as handling systems.

Lastly, Pillai adds, “We would like to show the top class production facility which gives the best quality, higher output and accuracy results in longer life for the machines. We are working on extensive dealer networks and franchisee systems to capture the major market share in this industry.”

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.