Introduction Reinforced concrete design and construction practice has historically focused on using bonded straight or bent rebar as a method for rebar anchorage. This relies on bond integrity between the rebar and the concrete for sufficient anchorage strength to be obtained. However, a bonded straight or bent length of rebar is not always the most effective or efficient anchorage method. There are many situations where the use of headed bars, sometimes called headed reinforcement anchors or “T” bars, is more desirable from a design perspective, more convenient from a construction perspective, or both.

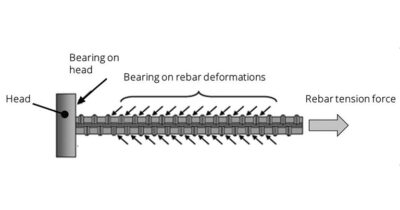

Headed bars are used as an alternative to the more traditional means of reinforcement anchorage. The load from the rebar is anchored via a head bearing or a combination of head bearing and rebar bond.The advantages of using headed bars are particularly apparent in heavily reinforced concrete, where rebar congestion and constructability are often problems. As a result, their use is now becoming more widespread worldwide, particularly within the civil infrastructure and nuclear new building sectors. Recent atomic power plants for headed bars include Taishan 1 China, Hinkley Point C UK, Akkuya Turkey, Flamanville France, Kursk Russia, and Ruppar Bangladesh.

In a heavily reinforced concrete element, there is often insufficient space for a straight or bent length anchorage. In addition, a bent anchorage often causes additional rebar congestion problems. The use of headed bars eliminates the requirement for a bent anchorage and allows the reduction of the bond/development length. In certain circumstances (code provisions permitting), they will enable the elimination of the required bonded rebar anchorage (development) length altogether. The resultant reduction in congestion facilitates concrete consolidation. Transportation straight lengths of rebar incorporating headed bars is easier than transporting rebar with bent anchorages, and on-site handling and fixing also become more manageable. The use of headed bars can offer a distinct time and cost advantage, as well as a potential improvement in concrete quality.

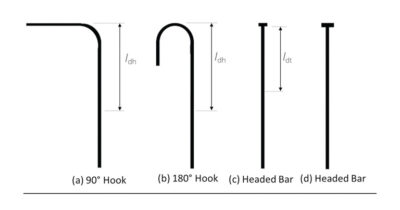

• ACI 318 90° hook. ldh = Tension development length

• ACI 318 180° hook. ldh = Tension development length

• ACI 318-headed bar. ldt = Tension development length

• Headed bar not requiring a bond/development length. Subject to certain criteria and code provisions Headed baffles can be used for various applications, such as beam-column joints, knee joints, pile caps, column-roof slab connections, cantilever element ends, within corbels, transverse shear reinforcement, and shear wall cross ties. Their use can be broken down as follows: The termination of primary longitudinal reinforcement, where the development length associated with a straight or bent bar anchorage would be an issue, or where there is rebar congestion. As a result, larger rebar diameters are usually associated with this application.

The termination of transverse shear reinforcement. The use of headed bars for this application is usually associated with ease of construction. This is particularly the case for seismically designed structures where code provisions require bends greater than 90° (typically 135°) and where, for quality control purposes, uncontrolled, on-site manual bending, or re-bending (to fit the rebar into position), is not allowed. These applications are, therefore, usually associated with smaller rebar diameters (typically 10–20 mm) and are of particular benefit for the shear reinforcement of thick slabs or rafts, where the headed bar can be dropped down into a position tied to the top layer of longitudinal reinforcement.

• Other applications include their use as an alternative to a standard rebar lap or rebar coupler splice by using overlapping heads and confinement, torsional, and punching reinforcement.

While ACI 318-19 gives a clear set of design provisions with headed bars, Eurocode 2 gives no explicit rules. Nevertheless, rules can be derived from the existing text. The Arup/Dextra Guide provides a detailed methodology for this process whereby the design load can be taken by head bearing alone or via a combination of head bearing and rebar bond, subject to various design parameters. The product standard ASTM

A970 states that the headed bar should comply with the standard, while the standard ISO 15698 is usually used in Europe.

The Indian code of practice IS 456 and IRC 112, as well as the design guide SP 34, allow the use of headed bars. IRC 112 has, in part, been derived from Eurocode 2. Therefore, the principles of the Arup/Dextra guide to designing with headed bars to Eurocode 2 could be implemented when IRC 112 is the applicable code of practice.

Types of Headed Bar

Most headed bar manufacturers produce products with at least two sizes of head. The smaller typically has a net bearing area of at least four times the cross-sectional area of the bar (a 4A head), to comply with the requirements of ACI-318, while the larger is typically

9A. 9A heads are usually selected because using this size can reduce the burden of ISO 15698 in concrete testing for static and fatigue loading qualification.

The heads are typically round, although some manufacturers produce square, rectangular, or other-shaped heads.

Summary

Heavy rebar congestion can lead to labour-intensive site placement and reduce concrete quality. Headed bars help reduce rebar congestion, facilitate concrete consolidation, and are easier to handle and fix on-site than traditional bent bar anchorages. The use of headed bars can offer a distinct time and cost advantage, as well as a potential improvement in concrete quality.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.