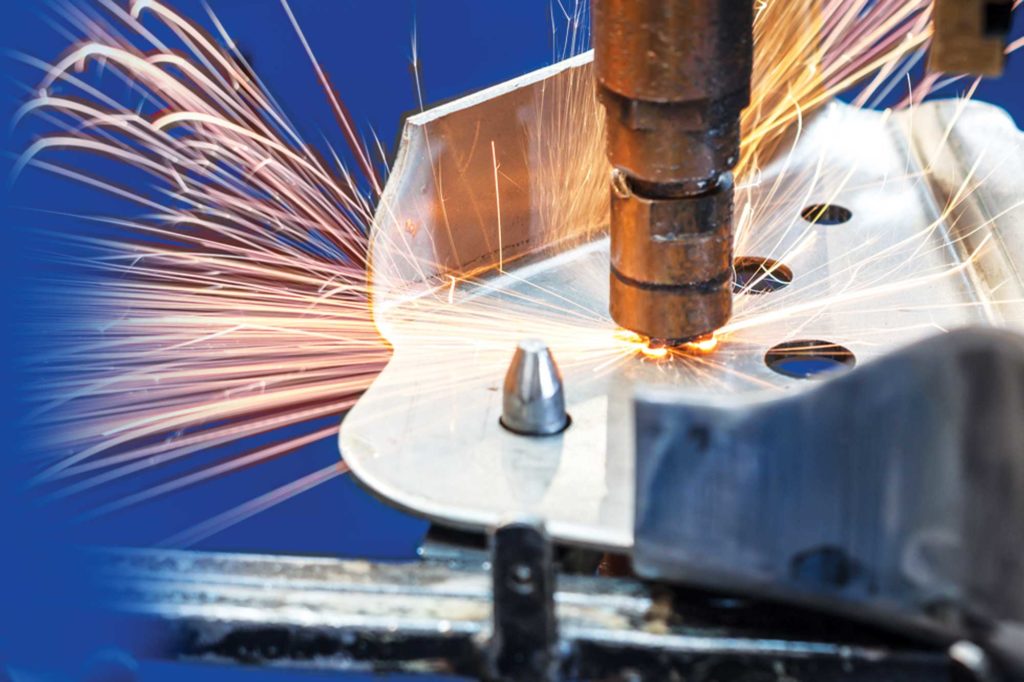

The electrodes are one of the most important factors in the resistance welding process but often one of the most neglected. To obtain the right quality welds consistently and high productivity with lower per weld cost, it is important to consider the electrode material, shape, size, tip profile and cooling.

A wide range of copper alloys are commonly used in resistance welding equipment and tools. For resistance welding of low carbon and high carbon steels welders most commonly use Class 2 and Class 3 (e.g. copper, chromium or copper, chromium, zirconium or copper nickel silicon) electrode materials. Class 2 materials give moderate life and eventually wear out since they lack strength and hardness properties particularly at elevated temperatures. Electrode materials are selected on conductivity parameters and properties like strength and hardness which are equally important but often neglected.

Class 2 and Class 3 electrode perform well for softer materials like mild steels or medium carbon steels but deform and lose its properties much faster when used on high strength steels – which are now commonly used in the automotive industry and other applications. For such cases Class 4 copper beryllium alloy are used to retain strength and hardness even at elevated temperatures.

Beryllium copper combines high strength with non-magnetic and moderate conductivity properties, which are necessary to weld high strength steels. It has many specialised applications apart from resistance welding electrodes like in tools for hazardous environments, musical instruments, precision measurement devices, bullets, and aerospace.

However copper beryllium comes with a two major disadvantages of high cost and health hazard – chronic beryllium diseases.

Chronic Beryllium Disease (CBD) primarily affects the lungs and can be fatal. CBD may occur among people who are exposed to the dust or fumes from beryllium metal, metal oxides, alloys, ceramics or salts. It occurs when people inhale beryllium in these forms. CBD usually has a very slow onset, and even very small amounts of exposure to beryllium can cause the disease in some people.

Copper Titanium Alloy is a material developed through a breakthrough innovative technology to potentially replace copper beryllium and some other copper alloys. This technology was developed by DRDO (Defence Research and Development Organisation) and has given exclusive license to Pahwa MetalTech Pvt Ltd to manufacturer this material and parts thereof, claim Pahwa MetalTech.

For more details, visit www.pahwametaltech.co.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.