Tata Tiscon, a ‘SUPERBRAND’ in innovation, is revolutionising construction. From 2000 onwards, it has evolved to offer innovative solutions like Tiscon ReadyBuild and Sm@rtFAB. This interview delves into their impact on cost, accessibility, and sustainability.

“Every Construction project seeks productivity, quality, and reliability at the site; rather, it handles tons of waste, cost overruns, delays, loss of working capital, struggles with reconciliations, safety, and manpower issues.” Prashant Kumar, Head, Downstream Business (TMT Projects and Solutions), Tata Steel Ltd.

What sets Tata Tiscon apart from other players in the market?

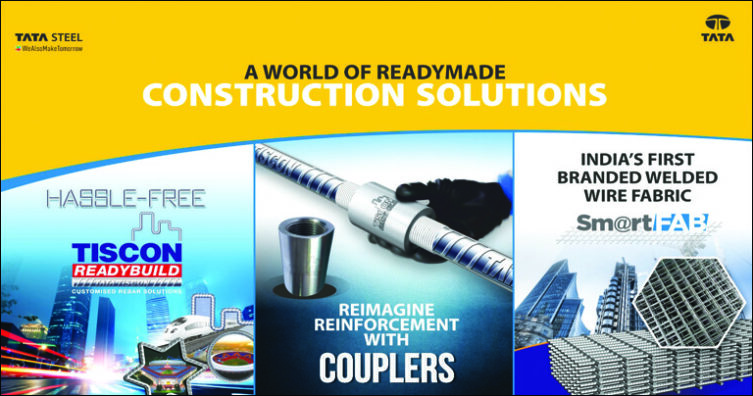

Tata Steel is always known for reliable and quality steel products. The journey of Tata Tiscon started in 2000, and we have come a long way from conventional TMT rebars to ‘ready-to-use’ reinforcement solutions like Cut & bend, Couplers, and Welded Wire Fabric. Our flagship state-of-the-art offerings are:

Tiscon ReadyBuild: Cut & bend is a ready-to-use form of rebars and rebar couplers with threading.

Sm@rtFAB: India’s 1st branded customised welded wire fabric solution, commonly known as Welded Wire Mesh.

This is a testament to our commitment to serving the changing needs of the Indian Construction Industry through our innovative solutions, thus setting us apart from other players in the market.

Could you offer a comprehensive breakdown of the cost-effectiveness associated with utilising Tiscon Readybuild and Sm@rtFAB in construction projects compared to traditional steel reinforcement?

The idea of proposing these solutions is more than just selling steel to the customer. Still, we understand the problems associated with construction projects and provide customized reinforcement solutions. Every Construction project seeks productivity, quality, and reliability at the site; it handles tons of waste, cost overruns, delays, loss of working capital, struggles with reconciliations, safety, and workforce issues.

Tiscon ReadyBuild saves up to ₹ 8000 PMT, and with Sm@rtFAB can easily save up to 30 percent of steel (~up to ₹10000 to ₹12000 PMT) in a project cycle. Both these solutions save time, cost, steel, and workforce requirements, ensuring site quality, reliability, and productivity.

How can a customer with a project in a remote location avail of these offerings?

We started with our first Construction Service Centre with 4000 TPM capacity in Bangalore in 2008. Today, we have 24 such service centres strategically located to cater to remotest locations. From border areas in the North-East to Leh-Ladakh, our service centres have served the most challenging territories.

In the future, we plan to extend our footprint to 48 construction service centres across India, which will offer customers One Stop Construction services and solutions.

How do Tiscon Readybuild and Sm@rtFAB contribute to addressing sustainability concerns within the construction industry?

Tiscon ReadyBuilld offers only finished shapes to the site. The model is based on scrap optimisation, thus reducing steel wastage and consumption at the site. Also, since these are made from GreenPro-certified rebars, consumers using this solution construct responsibly and promote eco-friendly construction practices.

On the other hand, imagine a 30% reduction in steel consumption at the design stage by using Sm@rtFAB as a solution; this drastically reduces the carbon footprint. Using these solutions helps the customers to generate additional Green Building Points, which to many have fetched an additional Floor Area ratio of up to 15%.

What are your latest reinforcement solutions?

We have been providing cut & bend solutions to customers, but we realised that customers who need Bore Pile Cages had to depend on conventional practices only. So recently, we have started providing customers with prefabricated Bore Pile Cages for two projects.

Also, now all our centres have rebar threading facilities for using Tiscon ReadyBuild couplers, ensuring that customers don’t get entrapped by on-site threading machine suppliers who ask for minimum billing. There is no minimum order quantity for coupler with threaded rebars supplied from our Service Centers. It is part of our complete Tiscon ReadyBuild solution. In Sm@rtFAB, we have started offering meshes that offer 550 MPa strength with a minimum 16% elongation.

What are some of the critical projects that you have served using these solutions?

We are proud of contributing to the National Growth Story of India by supplying our solutions to the prestigious Bullet Train project, Narendra Modi Stadium, Delhi International Airport, the recently constructed India’s first elevated Taxiway in Delhi, more than 15 Metro projects including the Delhi-Meerut RRTS project, all the 6 COVID Hospitals which were constructed in record time, and major commercial and residential projects.

Do you see the story of weaving for Tata Steel’s Tiscon ReadyBuild solution in the reinforcement industry as the story of RMC (ready-mix concrete) for the cement industry?

Of course! We do. The world is dynamic, and we understand the need to transform construction practices in India. Tiscon ReadyBuild’s way of construction will be the new normal in this decade only.

For more info visit : https://www.tatatiscon.co.in/

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.