Sivakumar M, AVP & Business Unit Head, TIDC India – Industrial Chains Division, Tube Investments of India Ltd. In an interview with B2B Purchase

Can you brief us about your company’s profile and its key offerings? TIDC India was established in 1960 as a manufacturer of bicycle chains. We are the pioneer manufacturer of automotive chains, industrial chains, fine blanked components, and other power transmission products. TIDC India’s customer section includes Mitsubishi Caterpillar Forklift America, Case New Holland, Bendix Commercial Vehicle Systems, Knorr Bremse, John Deere, Atlas Copco, FL Smidth, CLAAS, ONGC, Godrej, Kion, Honda Motorcycle, Hero Moto Corp, Bajaj Auto, Royal Enfield, Mahindra & Mahindra, Maruti Suzuki, Yamaha Motor & Ford.

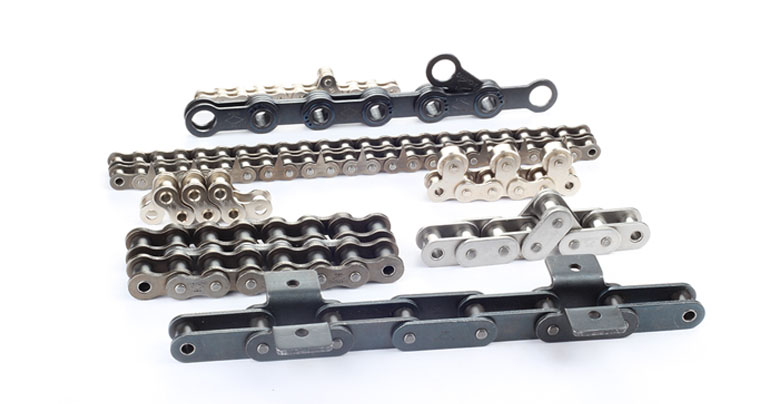

Industrial Chains Division was incorporated as a separate business unit of TIDC India to direct the supply of power transmission products to large industries and manufacturers. In no time, the IC Division has been a trailblazer in the manufacturing and supplying of Industrial Chains, Sprockets, Couplings, and many other power transmission products. The division has four manufacturing facilities, dedicated to the production of extensive categories of supreme power transmission products across agriculture, automobile, cement, steel, sugar, fertiliser, textile, food, and other sectors. All the manufacturing plants are well equipped for faster and quick through put conversion as per the customer demand with institutionalised Flexible Manufacturing System (FMS), Total Quality Management (TQM) and Lean Management System.

With over 60 years of experience in manufacturing excellence in the form of chains for varied applications, TIDC India has attained elite manufacturing capabilities. TIDC Industrial Chains Division has an in-house R&D and testing facility, new product development facilities, high efficient equipments, and a top – skilled workforce surpassing world standards with a magnificent TQM Approach.

Can you enlighten us about your manufacturing and engineering capacities?

We at TIDC India, believe in excellence and innovation while manufacturing our state-of the-art products. We have a team of over 150+ engineers who showcase their talents and utilise their skills to produce over 3000 varieties of industrial and automotive chains. The company has established a name of its own in the market owing to its excellent manufacturing capabilities, consistent performance, and delivering the highest quality.

TIDC India is a trailblazer and has significantly innovated the production process through cellular manufacturing. All our plants are integrated manufacturing centers with cellular manufacturing and have in-house tool engineering capabilities too. The entire manufacturing unit is assembled on structured operations as a stand-alone division for specific products. Our cross-functional team has always focused on the pain points of the customers and has mitigated problems through manufacturing intelligence. The state-of-the-art production mechanism and product testing have also aided in the improvement of our products.

TIDC India is a trailblazer and has significantly innovated the production process through cellular manufacturing. All our plants are integrated manufacturing centers with cellular manufacturing and have in-house tool engineering capabilities too. The entire manufacturing unit is assembled on structured operations as a stand-alone division for specific products. Our cross-functional team has always focused on the pain points of the customers and has mitigated problems through manufacturing intelligence. The state-of-the-art production mechanism and product testing have also aided in the improvement of our products.

The usage of the latest technology and supreme product design capabilities facilitate us to manufacture and deliver top-notch products to the customers for over six decades. And henceforth our clients recognise us as “The Complete Chain Company”.

The usage of the latest technology and supreme product design capabilities facilitate us to manufacture and deliver top-notch products to the customers for over six decades. And henceforth our clients recognise us as “The Complete Chain Company”.

It has further enhanced our manufacturing processes for material planning, tooling development, heat treatment and value added solution, assembly process, pre-loading and Lubrication.

What kind of R&D activities are required, and are required for manufacturing and installation of industrial chain?

Today, TIDC Industrial Chains Division is at such great heights of success only through our Engineering excellence. Our capabilities for engineering and innovation speak the volume of our achievements. Our capabilities motivated us to go an extra mile and achieve absolute superiority, while our capacities have made it possible to provide our products to everyone.

Our teams majorly focus on R&D sectors and have continuously delivered out-of-the-box solutions for our products and services. The ‘never-give-up’ attitudes of our skilled engineers and technicians have helped us to set new benchmarks in engineering. With such a robust working attitude from the employees and elite manufacturing practices, TIDC India has engineered world-class products for its customers. The team always aims at upscaling the design optimisation and performance requirements to deliver the finest quality at a competitive cost.

At TIDC Industrial Chains Division, we attain engineering excellence by having tie-up with our customers and explore new ideas to create value addition and empathetically solve the challenge faced by our customers. Together, we work on the product and process development at TIDC India. This customer-centric approach is at the core of our values, and thereby are vital part of our organisation. With such a constructive approach, we have been to reduce costs, improve efficiency, and uplift the quality of our products. Such is our unmatched brilliance in engineering that has let us establish a firm position and always stay at the highest summit in the chain industry.

Product Design: This is where the real magic happens! We at TIDC India manufacture the product as per our customer needs and shape with utmost compliance of art and science. Our aim is to design a product with a problem-solving approach and having exquisite quality.

Tool Design & Development: Our manufacturing plants have world-class equipments and smartest technologies to simulate, analyse, and fabricate the tool. This is where we develop tools with competitive costs, excellent capabilities, and supreme quality.

Product Testing: Our products are tested in extreme conditions to match the global standards of our customer base. The specialised machinery and equipment in our manufacturing plants can simulate any type of conditions to check every performance parameter of our products. Our Corporate Technology Centre enables TIDC India to do virtual simulation and prototyping of new products. It also gives us an opportunity to consistently improve the attributes, feasibility, and performance of our products.

Which sector do you serve the most, and how do you look at its business prospects in the near future?

We serve most to Sugar, Agriculture, Cement industries, Steel industries, Food and packing industries, Auto and automation Industries, Multi parking, Material Handling Industries, Mining, Construction, and Textile industries. The agriculture industries have future potential as the process of cultivating slowly changes from manual to automatic. As space constraints for parking Four-wheeler vehicles keep on arising in the urban areas. We have a fantastic opportunity for MultiLevel Car Parking. The market size of a multi-level car parking system is projected as 15cr in FY22. The Food industries started to move to Automatic from manual operation for the concern of Hygiene and also for faster operation. So, our chain with special attachments can be used in the food industry for transferring purposes. We manufacture leaf chain which is used in the material handling vehicles. The demand for leaf chains keeps on increasing YoY. To satisfy this demand we currently planning for the new plant which is especially for leaf chain manufacturing. We also have Good potential for construction machines as Road and paver business has grown by 10 percent.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.