This article shows how modern digitalisation offers a great degree of controllability in municipal wastewater treatment, prompting a higher quality of treated water.

The global population is projected to increase by 9.8 billion by 2050, and about 4.9 billion will come from Asia. At the same time, the increase in demand for water supply is expected to increase by 400 per cent in 2030. Due to the increased population and industrialisation, there will be a twin-edged problem in dealing with reduced fresh-water availability and increased wastewater generation in the coming years. Thus, enhancing our current wastewater treatment technologies to produce more clean water at a faster and more affordable rate is the need of the hour.

Despite the known benefits of wastewater treatment and reuse practices, their implementation in India is limited. Persistent water scarcity is the most crucial driver for wastewater treatment and reuse. At the same time, the most significant barriers are the lack of stipulation of pollution monitoring and control, the lack of an umbrella mandate for integrated water resources management, and limited cooperation between responsible governmental organisations.

To help rectify this growing concern, Danfoss has played a vital role in providing game-changing solutions that help extend our precious water and energy resources. Danfoss’ industrial water distribution and wastewater treatment solutions have made it possible to not only treat water but generate energy during water processing, fulfilling the energy needs of the entire water cycle.

Insights into the Water Treatment and Technology Space

Pressure control is critical to reducing water and energy loss Experience from 112 systems in 10 countries proves that

improved pressure control considerably reduces non-revenue water and dispensable energy consumption. Typical water leakage is reduced by 38 per cent, while energy consumption is reduced by 20–40 per cent. By saving 30 to 40 per cent of leakage, we can reduce energy consumption by 1.3 KWH per 1000 litres.

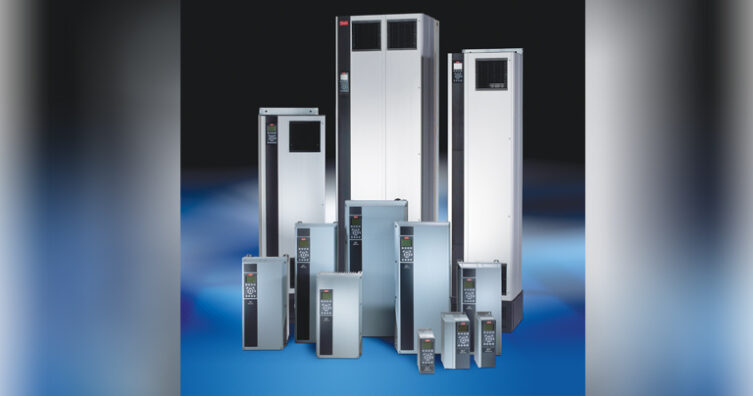

As the first to produce dedicated drives for the water and wastewater industry, Danfoss is a frontrunner in developing drives that address industries’ specific needs and challenges. Danfoss’ VLT® AQUA Drive not only combines deep application know-how with powerful drive technology to make water operation easier and more efficient but also saves installation and running costs.

Addressing water scarcity with efficient ZLD and MLD water treatment

Modern digitalisation offers a great degree of controllability in municipal wastewater treatment, prompting a higher quality of treated water. A zero-liquid discharge (ZLD) or minimal liquid discharge (MLD) treatment system improves water reuse and reduces industrial wastewater discharge.

When combined with optimised reverse osmosis processes, these progressive wastewater management strategies reduce energy consumption by up to 75 per cent. Danfoss’ series of APP pumps are specially designed and built for Zero Liquid Discharge and Minimal Liquid Discharge in industrial wastewater treatment. The pumps empower large-capacity industrial wastewater

treatment plants with high efficiency, robustness, and low operational costs.

The increased use of AC drives

Water and wastewater facilities account for 25–40 per cent of a municipal electricity budget, making them the single-largest electricity consumers. To counter this, extensive use of AC drives and advanced real-time online sensors are becoming the norm. AC drives control the speed of motors in a broad array of pump, blower, mixer, and dewatering applications to help boost performance while saving energy and costs. Controlling the aeration equipment with Danfoss AC drives can deliver energy savings of 30–50 per cent.

‘Bio refinery’ and ‘Water resource recovery facilities

They are the most advanced cases, where energy recovered from the wastewater treatment process covers not only the plant’s needs but also wastewater pumping and energy needs for drinking water production and distribution. In other words, the whole water cycle can be considered energy neutral, and waste can become a source of energy.

Developing technology-guiding frameworks and strengthening institutional and monitoring capacity is crucial to increasing confidence in the quality of recovered water resources, creating demand, and ultimately safeguarding human health and the environment. Successfully enforcing reuse strategies will depend on the holistic evaluation of local factors such as governmental incentives, social acceptance, and legislation harmonisation related to cost, risks, and environmental performance.

As we advance, it is vital that reducing energy consumption is in focus for industrial and domestic wastewater treatment for both sustainability and economic reasons. The good news is that technologies to reduce energy consumption and leakages in all stages of the water cycle already exist. With advancements in digitalisation, Danfoss VFD Solutions offer predictive maintenance and condition monitoring features like load profiling, which further improve energy efficiency. Not only can the water cycle be made more efficient, but it also has the potential to generate energy. Moreover, as part of optimising the energy consumption in the water distribution system, water

leakage will be automatically reduced. Thus, less energy will be used, and less water will be wasted.

We at Danfoss believe in a resource management strategy that is good for the planet and the pocket.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.