Godrej, in collaboration with Tvasta, is building a climate-responsive security pavilion, showcasing 3D printing’s future impact on construction.

Abhijeet N Gawde, Head of Business Development & Marketing at Godrej Construction, highlights the company’s dedication to environmentally friendly construction materials. They have attained GreenPro Certification for products like Ready-Mix Concrete (RMC) and integrated green energy practices.

The Godrej TUFF brand offers a breakthrough range of customised and environmentally-conscious products in construction materials. Godrej & Boyce has always been committed to preserving the environment and aims for more sustainable development. In line with the core values of Godrej & Boyce, Godrej Construction (GC) has implemented various initiatives across its lines of business.

Godrej’s GreenPro Certification and Commitment

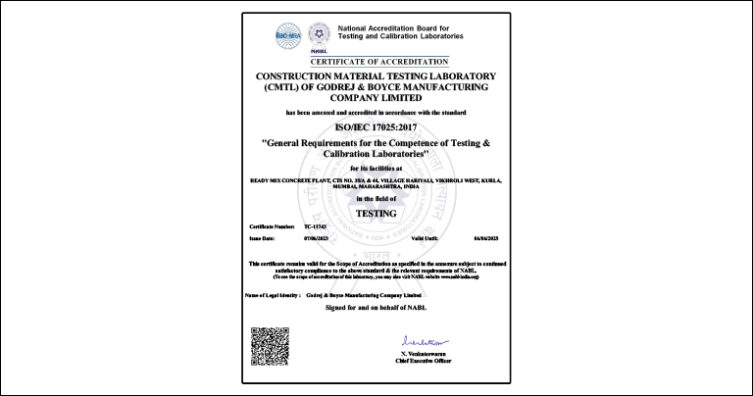

Godrej Construction has received the ‘Green Pro’ certificate from Indian Green Building Council (IGBC) for their Ready-Mix Concrete (RMC) products such as Enviro TUFF, Xtra TUFF, Easy TUFF and other construction materials such as TUFF Blocks AAC, Recycled Concrete Blocks & Pavers making them beneficial for use in Green Buildings. Our 3 RMC plants in the Mumbai-MMR & Pune region have been commended with the GreenPro Certification by Indian Green Building Council (IGBC). Godrej Construction is one of the first in the RMC industry to switch to 100 percent green energy. Our RMC Central Quality Laboratory at Vikhroli recently received a ‘Certificate of Accreditation from National Accreditation Board for Testing and Calibration Laboratories (NABL) by ISO /IEC 17025:2017. NABL accreditation reinforces our commitment to achieving quality excellence for our products and services.

Leading the green revolution in construction and development

Our Construction Materials team has undertaken various pioneering initiatives over the last few years to address multiple challenges faced by our customers within the Real Estate and Construction industry. To provide a seamless customer experience, we have leveraged digital technology by developing a unique mobile application, the first of its kind in the industry, known as the Godrej Go Tuff app. Godrej Go Tuff app is enabled with convenient features like real-time delivery tracking ensuring transparency to optimise and manage every step of construction material supply from order to delivery.

Concrete Testing Squad Van by Godrej Construction offers quality testing services at your worksite. It enables faster turnaround of the approval process of ready-mix concrete mix design by our customers, as the results of mix design trials, cube testing, compressive strength, and sieve testing can be measured in a few hours.

From on-site concrete-testing vans to a Construction Materials Godrej Go Tuff app, we provide unique and efficient services that ensure the highest product standards and customer satisfaction.

Globally, the construction sector is amongst the largest consumers of natural raw materials. For an industry vulnerable to raw material supply problems and price volatility, it does make sense to focus on resource efficiency and the reuse of materials. With new buildings and infrastructure projects construction work rising, the demand for building materials is expected to increase. However, a crisis is looming in the construction sector as there is a growing shortage of building materials. As per the World Green Building Council’s report, building and construction are responsible for 39 percent of all carbon emissions in the world, with operational emissions (from energy used to heat, cool and light buildings) accounting for 28 percent. The remaining 11 percent comes from embodied carbon emissions associated with materials and construction processes throughout the building lifecycle. Broad-based recycling of construction materials coupled with smart design could substantially reduce CO2 emissions generated by buildings.

Recycling and innovation for a greener future

Godrej Construction uses the principles of “Recover, Recycle and Rebuild” for recycling concrete debris to produce prefabricated concrete products such as building blocks, pavers, culverts, ducts and other customised precast concrete products.

Godrej Construction has set up an automated Recycled Concrete Materials (RCM) manufacturing plant at Vikhroli, Mumbai. This industrial plant manufactures concrete blocks for walls and pavers using concrete debris recycled from demolished concrete structures from building and infrastructure projects, which would otherwise end up in overflowing city landfills. By implementing circular economy principles, we have recycled over 30,000 metric tonnes of concrete debris so far.

Concrete recycling and 3D printing

Recently, Godrej Construction, in collaboration with Tvasta, an IIT Madras start-up, has meticulously designed, engineered, manufactured and erected a unique Security Pavillion structure by deploying a fully automated Robotic Arm 3D Printer, a homegrown innovation by Tvasta. This Security Pavilion is thoughtfully designed and developed to be climate-responsive. We used a fully automated Robotic Arm 3D Printer to demonstrate the robust application of ‘Modular Design’ and ‘Parametric Architecture’. This new development serves as a testament to the potential of 3D printing technology and its likely impact on the Real Estate & Construction industry in the years ahead.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.