Arc welding is the most preferred welding technology due to its low cost and can be applied to a wide range of metal surfaces.

The welding materials market is projected to grow from USD 13.6 billion in 2020 to USD 17.3 billion by 2025, at a CAGR of 4.8 percent during the forecast period. The welding materials market has grown considerably in recent times due to the development of the transportation industry and growth in the building and construction activities in emerging economies such as China and India. This is expected to remain a key driving factor for the market over the next five years. However, environmental impact of welding materials shortage of skilled labour and high labour cost restrain the growth of the market.

Covid-19 impact on global welding materials market

The welding materials industry was majorly impacted by COVID-19. In the initial stages of the pandemic, factories in several countries were forced to shut down as the governments implemented strict lockdowns to stop the spread of the virus. After the lockdown was lifted and restrictions were eased, welding material manufacturers were allowed to resume factory operations but at a limited capacity and under several rules and regulations.

According to an analysis conducted by “MarketsandMarkets”, the demand for welding materials also reduced as the majority of the demand is linked to the end-use industries, which are also facing difficulties operating during the pandemic. Many construction projects and activities, including government infrastructure projects, which were initially running, came to a complete halt due to the imposition of lockdowns. The construction industry, like many others, is labour-intensive. Mass unemployment in the construction industry led to widespread panic, leading labourers to return to their homelands to sit out the pandemic. Even after the easing of restrictions in several countries, construction companies are working with reduced finances, labour, and working hours, which will further impact the project delivery timelines.

The impact of the slowdown of the construction industry was felt by the welding materials industry as well. Apart from the shutdown of production facilities, the cancellation of several projects in the commercial and industrial construction sectors reduced the demand for welding materials in 2020.

Welding materials market dynamics

Driver: Increasing demand from end-use industries Welding is widely used in the transportation industry to manufacture various vehicle body parts and possesses the same strength as the materials being joined. In 2019, the transportation end-use industry constituted 34.42 percent of the total welding materials market. According to OICA (Organisation Internationale des Constructeurs d’Automobiles), the global production of passenger cars amounted to 67.14 million. Although the production of vehicles saw a decline of approximately 5 percent in 2019 from 2018, there is still a large scope for growth of the welding materials market in this industry. Innovations and technological advancements in the automotive industry to cater to the growing demand from customers is expected to create a high demand for welding materials during the forecast period.

Welding materials also find applications in the building and construction industry, which is growing at a steady rate, especially in the emerging economies of India, China, and Brazil. In these countries, new infrastructural development projects are likely to drive the welding materials market.

The growing demand for welded steel for the construction of residential and commercial buildings is expected to drive the market during the forecast period. According to the Global Construction Perspectives and Oxford Economics, the global construction output is expected to grow by 85 percent and reach USD 15.5 trillion by 2030, with three countries – India, China, and the US leading the way and accounting for over 50 percent of the global growth. This growth in construction output will positively impact the market for welding materials.

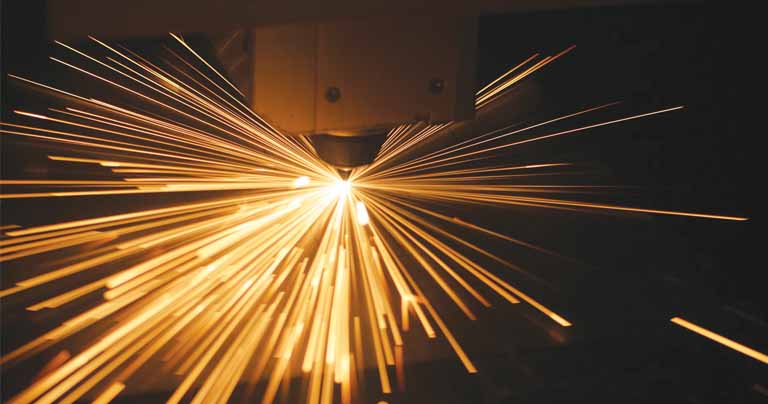

The arc welding segment is projected to lead the global welding materials market through 2025

Arc welding has the advantage of high heat concentration during the welding process wherein an electric arc is produced in between the electrode and base materials that melt the metals. The major advantage of arc welding is the concentration of heat applied to a large surface that enables better welding by providing a depth of penetration, which ultimately reduces the welding time. Arc welding is the most preferred welding technology due to its low cost and can be applied to a wide range of metal surfaces.

The fluxes and wires segment is projected to grow at the highest CAGR in the welding materials market during the forecast period

The fluxes and wires segment is projected to grow at the highest CAGR in the welding materials market from 2020 to 2025. Flux is a chemical agent, which is used to clean a surface or can be used as a purifying agent. The flux material is used to dissolve the oxides by releasing gases that are trapped on the surface. Fluxes also help remove the impurities from the base metal surface that can further provide a good blending between the base metal and the filler material surface.

Opportunity: new and advanced applications

Welding techniques such as laser welding and ultrasonic welding are witnessing increasing adoption, which, in turn, is propelling the welding materials market. These welding techniques have high efficiency and several advantages that make them suitable for numerous applications. These techniques are becoming increasingly popular in end-use industries where precision and accuracy of the joints have high importance, such as electric appliances, robotic appliances, and moving automotive parts. The demand for welding materials will be further propelled as welding is the only joining technique that can be used in space and underwater. Welding plays an important role in the repair of ships, pipelines, and offshore oil platforms. Underwater welding is also becoming an emerging technique in marine applications. Additionally, it is used by end-use industries in repair and maintenance operations. To reduce the weight of car bodies for lower environmental load substance and workability improvement, steel materials are required to have super high tensile strength and be able to deal with complex structures of parts with high performance. In the field of thick plates and steel pipes, the trend of mega-structural construction and high-efficiency transportation creates the demand for thick and high tensile strength steel products. To fully utilise such advanced steel products, the advancement of welding technologies is necessary. Various welding technologies have been developed and applied with the progress of steel materials. The transportation and automobile industries are among the biggest consumers of welding materials.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.