LPS-EJOT’s German-manufactured fasteners have been produced in closed co-ordination with system manufacturers and suppliers to position them among the best in the market.

The Company claims that working closely with system manufacturers and suppliers, LPS-EJOT has both widespread international approval and application-specific products, gaining broad acceptance from suppliers, engineers, buyers and installers. The company aims to improve, optimise and enhance the boundaries of performance, going beyond the benchmark to set new higher standards, both locally and globally. The process ranges from simple pullout tests, to complex system and application testing down to metallurgical and chemical com- position.

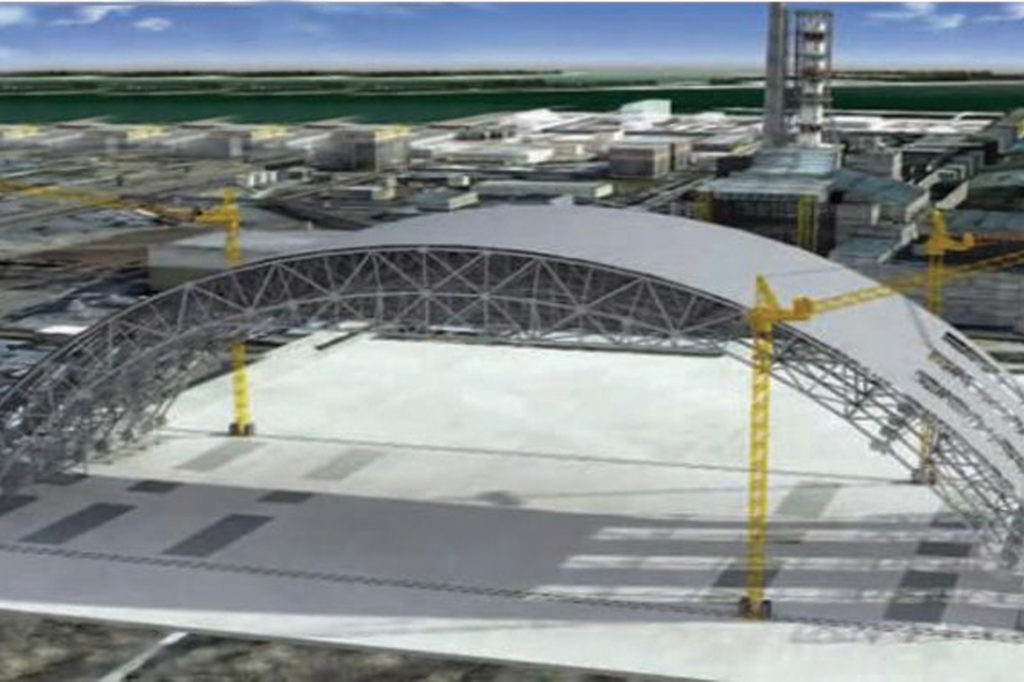

Chernobyl Reactor

The worst nuclear disaster in history occurred at the Chernobyl nuclear power plant in Ukraine on April 26, 1986. Since then, a provisional sarcophagus has entombed the reactor, but the porous construction, built to last for only 20 to 30 years, leaks water and dust can escape. The current stabilizing construction work will protect the rusty protective cover from ‘crumbling’ until around 2023.

The new protective cover, named the Chernobyl arch, securely confines the remains for the next 100 years. It will be constructed with fasteners from LPS-EJOT. For that reason, the cover is being built on neighbouring premises and will be pushed over the existing structure. All production and processing steps are monitored continuously, from the incoming goods inspection of the raw material all the way to its final inspection the identity check claims company. This is where LPS-EJOT scored the vital points as it maintains its status as one of the world’s leading manufacturers of fastening solutions. Standardized manufacturing processes as well as in-house testing according to the specifications of the LPS-EJOT (European Organization for Technical Approvals) are guaranteed.

Chernobyl Arch

The name of the project is Chernobyl New Safe Confinement which is also known as the Chernobyl Arch. The arc is a construction of a new cover for the destroyed reactor block four of the construction companies. EJOT products used which is been used is namely Super-Saphir self-drilling screw of the JT3-family.

Function of the shield

• Secure encasement of the reactor Block Four for at least 100 years.

• Protection from corrosion and other aggressive environmental influences.

• Prevention of water penetration and release of radioactive dust.

• Enabling the dismantling of the unstable remaining structure.

• Enabling the recovery of the fuel rod remains.

Design

• Proven steel structure made of 16 arch-shaped braced metal pipe constructions to minimize repair and maintenance work.

• Installation of a crane to dismantle the old cover structure.

• Attached gable walls enable pushing of the structure over the reactor.

• A double-walled outer skin is attached to the structure in order to seal the inside from the outside thereby isolating it from weather exposure.

• External cladding and internal cladding with approximately 13.8 m of space in between.

• Temperature and relative humidity can be regulated.

Dimensions

• Weight: 29,000 tons

• Span: 257 M

• Length: 164 M

• Height: 109 M

Application

• Fastening trapezoidal profiles on steel purlins.

• Fixing the inner and outer cladding.

• Fixing the top hat section to the trapezoidal profile.

Contact:

LPS-EJOT Fastening Systems Pvt. Ltd.

Tower – A, 5th floor, 501-502,

Millennium Plaza. Sector 27,

Gurgaon – 122003.

Haryana, India.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.