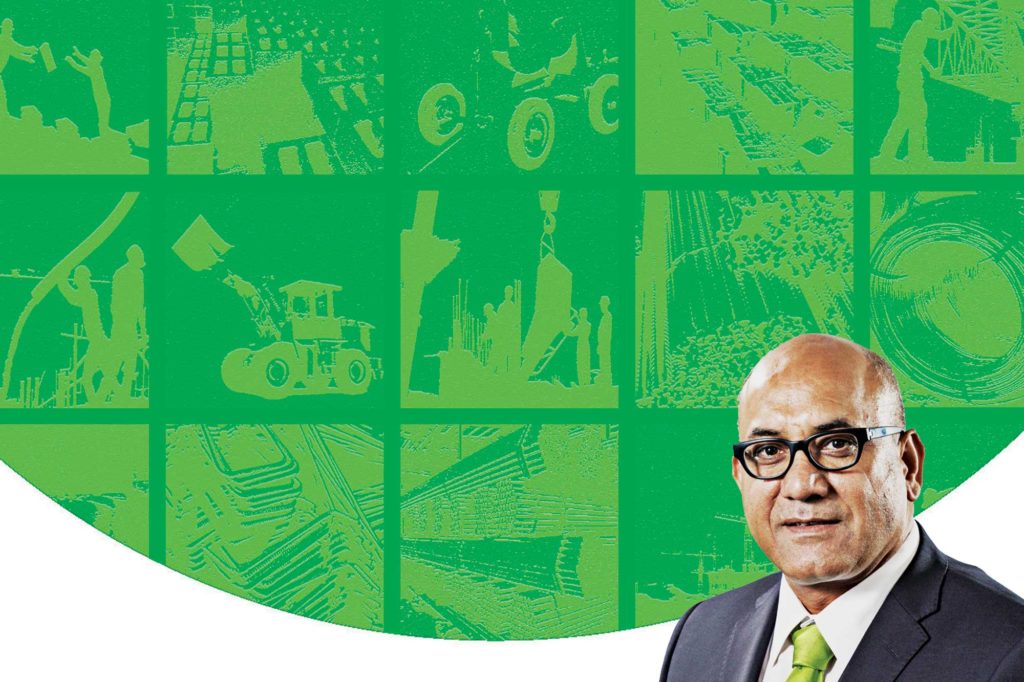

Elematic is a supplier of precast concrete technology worldwide. Elematic works in over 100 countries and supplies anything from a single machine to a production line and to a complete precast plant. Chander Dutta, Managing Director at Elematic India Pvt Ltd emphasises on the nascent stage of precast concrete in India and its growing opportunities in the years to come.

Creating awareness

India is a land of opportunities and there is a huge demand of housing in affordable housing sector. As per 2011 census, there is shortage of almost 30 million housing units and the country is urbanising at the average rate of 10-12 per cent, thus it creates further opportunity for housing units.

Elematic had started its operations in India in 2007. “In the past eight years we have put a lot of efforts to convince government, authorities and end-users about benefits of precast concrete technology. People have started accepting the technology, but still I would say that precast technology is in budding stage and have humongous opportunity with great challenges,” said Chander Dutta.

Buying factors

Precast concrete technology requires accuracy and precise working. Explaining the quality control at Elematic, he said, “In precast, we follow 3P principle which is planning, proper planning and perfect planning. We do not accept any mismatch in the production.”

Elematic offers a range of machinery to meet daily production requirement and it can supply two tables to produce 600 sq. ft. daily to a precast plant capable of producing 25,000 sq.m. of precast elements. Elematic claims to have supplied the world’s largest precast plant.

Explaining the major factors a buyer should consider before making a decision of procuring precast concrete technology, Chander Dutta said, “A buyer should start with small investment and choose the precast plant which could be easily expandable in future. The project should be designed keeping precast technology in mind.”

Elematic India has a team of almost 90 people serving closely to the customers. It provides all solutions under one roof and helps their customers to develop precast friendly layouts to economise construction.

Major innovations

According to Chander Dutta some of the major innovations happening in the area of precast concrete include structural design codes, precast machinery, jointing material, and other related equipment like B&M plants and cranes. Powered by strong R&D, Elematic is creating its mark in precast space.

India at budding stage

Commenting on if India is ready to make optimum use of advanced precast concrete, Chander Dutta said, “Indian precast industry is in very nascent stage and require hand holding support for successful execution.” Elematic India has a team of 50 service engineers or technicians who provide complete support and training for production, erection and other related services in order to achieve best results of precast technology.

Elematic India’s offering

Elematic is one of the leading suppliers of complete precast plants, machinery and equipment worldwide. With the experience of working in more than 100 countries, Elematic has proven capability and required resources to deliver complete precast factories anywhere in the world. Elematic has almost 60 per cent share in Hollow Core Slab and 40 per cent share in overall precast market globally. Elematic has 450 patents and has delivered more than 4,000 precast plants around the globe. In India, Elematic provide end-to-end solutions to its customers which are:

• Concept design study

• Supply precast machinery

• Precast plant design

• Precast plant setup

• Production training

• Precast element installation training

• Complete structural engineering services.

Elematic has all solution under one roof and offer technology for the production of the following precast elements such as:

• Pre-stressed floors/slabs (solid and hollow core)

• Acotec non-load bearing partition walls (thickness 64 – 140 mm)

• Column, beam (pre-stressed)

• Facades, load bearing walls (80 – 250 mm)

• Staircases

• ERP software.

Reduce technology cost for buyers

Elematic has introduced “SEMI” precast plant targeting Indian market. The SEMI precast plant can produce 1 million sq. ft. BUA yearly with 40-50 people working at the plant. Chander Dutta says, “Elematic is putting efforts to arranging all required skill sets including machinery, structural design solutions, service team, and concrete experts to bring down total project cost.”

Elematic has established a state-of-the-art production facility in Alwar, Rajasthan to produce moulds and other small machinery in India which is expected to help its customers to save 40-50 per cent cost. “Our main idea is to bring down cost of technology so that it could be within the reach of all small or big developers,” said Chander Dutta.

——————————————————————————————————————————————————————–

A buyer should start with small investment and choose the precast plant which could be easily expandable in future.

Chander Dutta, Managing Director, Elematic India Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.