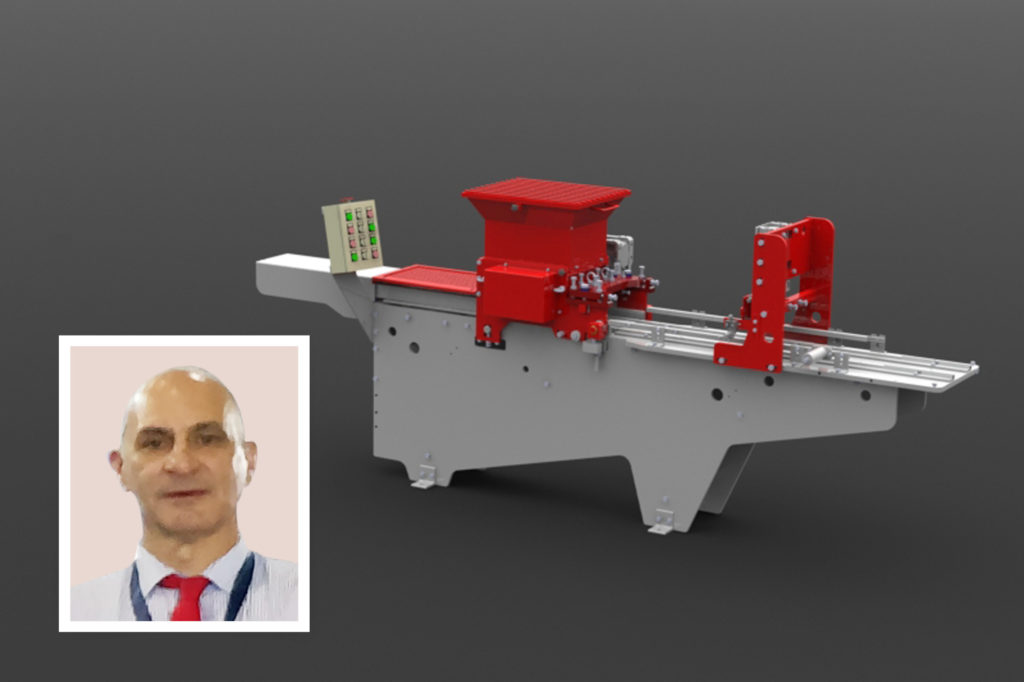

We expect that our innovative tile-making machines would find acceptance in Indian market due to their unique technical features and aesthetic appearance.

Paul Packer, Sales Area Manager, Vortex Hydra S.r.l.

Headquartered in Italy, Vortex Hydra S.r.l. is one of the global leaders in designing, building and installing manufacturing plants to produce concrete roof tiles. The company has celebrated its 50th year in business in 2017.

At EXCON 2017, Vortex has introduced its concrete roof tile-making machine in India in partnership with Columbia Machine Engineering (I) Pvt Ltd. Present at the occassion, Paul Packer, Sales Area Manager, Vortex Hydra S.r.l. said, “During the last half-century, Vortex has helped many building companies and businessmen to get started in the production of the concrete roof tile, a product that is relatively unknown in the Indian sub-continent. We expect that our innovative tile-making machines would find acceptance in Indian market due to their unique technical features and aesthetic appearance.”

Paul informs that concrete roof tiles are much better than any other pitched roof system. Explaining the advantages of concrete roof tiles, he said, “In Europe the concrete roof tile is widely used as it enhances the appearance and value of a property. It also offers excellent technical features. Concrete roof tiles are also considered as environmental friendly.”

Widely used in European countries, concrete roof tiles offer complete resistance to extreme climates, withstands the ravages of weather and hazards of fire, permanent colour is assured, unique strengthening reduces breakage during handling and transportation, good insulation characteristics and permeability with age.

“During its entire lifecycle, a concrete roof tile only causes about 45 per cent of the greenhouse gases of that triggered off by a clay tile therefore are environment friendly,” Paul said.

Vortex Hydra tile-making machine can also be used for making floor and wall tiles.

Extrusion process: The proven technology of extruding a semi-dry concrete mix between a continuous flow of aluminium pallets which pass through an extrusion head is widely used for roofing siding and floor.

Main advantages: Good quality products, high production speed, low operational and maintenance costs, variety of tiles profiles by simply changing aluminium pallets and extrusion tooling, and locally available raw materials.

Raw materials: For roofing tile (size 420×330 mm approx. 10 tiles/sq.m.) 3.3 kg sand, 1.1 kg cement, 30-40 grams oxide pigments and water for a tile weight of 4.5 kg. This mix can be revised to suit the actual quality of sand and cement.

Vortex Hydra entry-level machines begin with the UNO Starter Pack which can produce enough tiles to roof a small family house in just 8 hours. The machine is shipped in a 20-foot container which later converts into a curing chamber in which to dry the tiles. It is also possible to buy the kit at a slightly higher price with an extra machine included for making floor and wall tile at the same time.

The Vortex family of machines progresses with the Uno Evoluzione machinery range. According to Paul, this is the ideal solution for those wishing to get start in the concrete roof tile manufacturing business with a low initial investment and the possibility to easily increase the production capacity up to 4 times more without buying a 100 per cent new line.

Uno Evoluzione systems production range varies from 2,000 to 16,000 tiles per shift.

Vortex wet cast techniques are used to produce high quality decorative concrete products such as architectural stone, stone veneers, ornamental bricks, and brick veneers with different types of surface finishing.

For more details, visit www.vortexhydra.com or contact at sales@colmac.in

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.