At present, there is a huge demand for Screening media solutions to cater to the ongoing infrastructure projects in India. Moreover, the artificial sand market has taken the demands to the next level, resulting in overall growth and profitability.

With its innovative, complete screening media solutions, Ashar Locker India Private Limited is at the forefront of the mining and quarry industry’s transformation. This interview provides a thorough examination of their dedication to innovation in technology, environmental sustainability, and quality, all of which are driving demand and establishing new benchmarks for the industry.

Can you summarise Ashar Locker ‘s journey in providing screening media solutions for the mining and quarry industry?

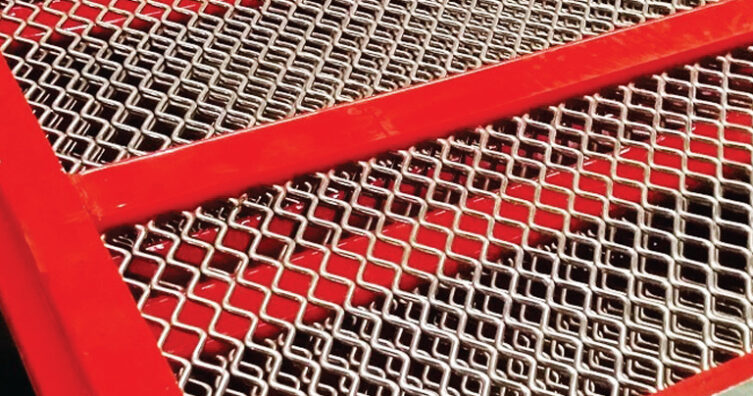

Ashar Locker is a Joint venture partnership between Ashar and Locker Group (Valmont Industries). Locker Group has dominated the screening industry in Australia for several decades, and our family has been involved in similar engineering businesses for just as long. The vision was to bring world-class manufacturing capabilities adopted from Australia to service the world via India. Ashar Locker is a one-stop shop for all screening applications and is the only Indian manufacturer to offer a complete range of products under one roof. This allows us to offer our customers complete screening solutions and prove our industry-leading quality through our many onsite audits and performance reports. Passion, Integrity, continuous improvement, and delivering results are the foundation for our core value, value creation for our customers.

How have you observed the screening media solutions industry evolving in recent years, and what trends do you anticipate for the near future?

We have always believed in innovation & technology, and our products have been in huge demand across all the minerals in the industry. We are a total solution provider, differentiating us from our other suppliers in India. Our dedicated R&D team has always focused on developing products that create value for our customers. Some of our flagship products, like the Anti-clogging screens, have been trendsetters in the industry, enabling our customers to operate their plants during heavy monsoons. Going forward we may develop more advanced solutions which may bring disruption in the screening industry.

What are the critical factors influencing the demand for screening media solutions in the mining and quarrying sectors?

Over the years, there has been a significant shift from customers to good quality products. Our customers now understand the importance of products that add value to their processes, resulting in higher productivity and lower costs per ton on their screening. Our regular onsite plant audits and performance reports help them improve their product quality as per their customer demands.

At present, there is a huge demand for Screening media solutions to cater to the ongoing infrastructure projects in India. Moreover, the artificial sand market has taken the demands to the next level, resulting in overall growth and profitability. This year, the mining market has also shown some significant growth, and hence, we expect the demand to further improve over the next few quarters.

What sustainable practices or innovations have gained traction in the screening media solutions field?

At Ashar Locker, we strive to ensure that our products are not just efficient but also environmentally sustainable. For example, many of our competitors use a chemical named MOCA for manufacturing Poly-urethan panels, which is very toxic and is responsible for causing cancer to the people involved in manufacturing these panels. This is done to save cost. Moreover, when a customer uses any of such panel at their site, they are exposing themselves to harmful emissions coming out of these panels when exposed to sunlight. We at Ashar Locker do not use any such materials that may harm our employees, customers & the overall environment.

It is not just our responsibility but also the customers’ responsibility to ensure that they ask the right questions to their supplier during the procurement stage to ensure that such chemicals are not being used for their products. It is only then that environment-sustainable products will continue to grow in the market.

Can you shed light on the industry-wide quality standards and compliance requirements that screening media solutions providers must adhere to?

Ashar Locker’s approach to the industry differs from the competition in several ways; our engineers focus on the application and need of each customer’s unique setup to deliver a screening solution that increases throughput and reduces downtime to achieve a lower cost per ton of screening. Our performance reports show that Ashar Locker’s screening solutions outperform the competition by many folds in several cases. We have over five decades of experience in the Screening segment, and we are the only manufacturer in India to provide a complete screening range to all our customers. We procure our wires from either Tata Steel Ltd or other equivalent wire manufacturers from across the world. Unlike other competitors, we do not offer different quality for different markets. Our quality is per Global standards, and therefore, our customers experience the same quality worldwide. Also, our unique design and state-of-the-art manufacturing facility enables us to maintain strict tolerance limits for all our meshes.

What technological advancements impact the screening media industry?

As a company, we recognise the importance of technological disruptions and constantly seek ways to leverage them to improve our operations and services. Our future strategies are focused on innovation, product development, and enhancing our digital capabilities to improve our customer experience. By staying at the forefront of technological advancements, we can drive growth and success in the long run.

Ashar Locker’s anti-clogging screens have proved to be highly successful in manufacturing M-sand and P-sand over the past few years. These handmade and uniquely designed screens utilise every motion of the screen efficiently. Every wire vibrates individually, which not only improves the efficiency of the plant but also helps in developing precise cuts needed for sand manufacturing.

The Rubber & PU meshes, when compared to the wire mesh, have a better wear life, less dust generation, less sound pollution, and are more durable. The only drawback is the reduction in open areas for screening. Non-metallic and metallic have their place and importance, and customers are guided to install the right combination of the meshes to bring value to their plant. The top deck can be non-metallic, the second one metallic, and the third can be an anti-clogging screen; this can be decided with the help of the company’s expert technical team.

Spokesperson – Vasim Pradhan, Head Sales – India & International Business, Ashar Locker (India) Pvt. Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.