This is a brief project report of a Pavement Subsurface Drainage using TechDrain Drainage Composite by TECHFAB INDIA INDUSTRIES LTD., for NH-44 at Agartala, Tripura.

Water in pavement systems is one of the principal causes of pavement distress. Pavement drains are provided to remove infiltration water from the pavement layers and to prevent infiltration of water from the shoulders, verges, and medians into the pavement. It is well known that improved roadway drainage extends the life of a roadway system.

Most water in a pavement section infiltrates the pavement surface during rain events. Including an open-graded, free-draining sub-base layer in the pavement section provides drainage, and using free drainage aggregate has been the standard practice of many engineers who design pavements for extended service life. However, there have been many instances where the desired gradation of gravel is unavailable, the pores of the gravel layer getting clogged etc., which leads to long-term failures of road pavements.

In continuance to the Circular of the Ministry of Road Transport and Highways (MoRTH) on “Geo synthetics and their use in road construction “issued in July 2018, IRC SP59:2019 “Guidelines for the use of Geo synthetics in Road Pavements and Associated Works” has been published in August 2019 and IRC 37:2018″Guidelines for Design of Flexible Pavements” has been published in November 2018.

A maximum of states in the country are facing acute problems with sound quality granular material availability. The focus has shifted to adopting Cement Treated Sub Bases (CTSB) as an alternative. Witch’s, there is a maximum reduction in the use of good quality granular sub-base(GSB) and quantum of gravel material due to the use of cementitious materials to compensate for the strength of the granular sub-base (GSB).

In such conditions, and with the provisions of IRC SP 42:2014, IRC37:2018, IRC SP 59:2019, MoRTH 700 Specifications and circulars/initiatives of NHAI, it is high time to push for drainage composite in flexible pavements with Cement Treated Sub Bases (CTSB).Also, In the case of rigid pavements, the granular sub-base, which is exclusive to serving the purpose of subsurface drainage, can be replaced with drainage composite wherever it proves cost effective. This case study discusses thepossible causes of flexible pavement failures with poor subsurface drainage under high infiltration and capillary rise conditions and recommends Tehrani Drainage Composite for subsurface drainage instead of conventional gravel drainage.

Project brief

Special Accelerated Road Development Program for the North East (SARDP-NE) for the North Eastern Region and Sikkim is a specially designed highway development program for the North Eastern region. The Ministry of Road Transport and Highways has formulated SARDP-NE for enhancing road facilities in the North-East region.

The scheme’s objectives are the upgradation of national highways connecting state capitals with 2-lane or4-lane roads. NH 44 was planned to be improved to a two-lane highway from km6.800 to km 55. 000.

There were significant challenges to achieving the objectives as the availability of aggregate for the construction of pavement structures was scarce, and even the available resources were of marginal quality.

Solution proposed

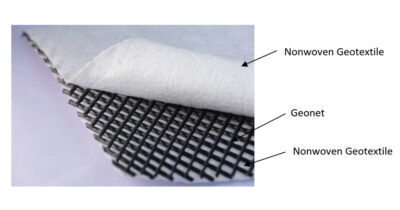

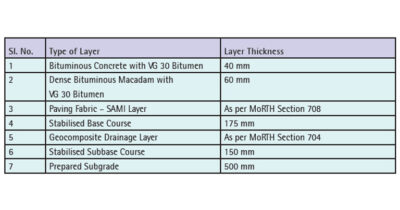

After carefully evaluating the project requirements and site conditions, the Central Road Research Institute (CRRI)has conducted a detailed analysis and approved the usage of Tech drain Drainage Composite TDC 55130, which is in accordance with the requirements of MoRTH specifications section 704.The pavement designs submitted tori were reviewed using IIT Pave software, permissible strains were computed using IRC 37:2012, and the layer thicknesses were recommended as tabulated below:

As per IRC 37 Clause 7.2.2, it is required that the stabilised soil layer should retain permeability when waters likely to enter the pavement from the shoulder, median, or through cracks. It was therefore recommended that Tech Drain Drainage Composite, which possesses the required permeability and facilitates the subsurface drainage, be laid between the base and sub-base layers. It was ensured that the composite drainage layer for the sub-base layer, including the shoulders, ran up to the end of the toe. The following is the typical cross-section of the pavement structure adopted for construction.

Present status

Techfab India has supplied the entire quantity of Tehrani Drainage Composite within the stipulated time and met all the quality requirements. KMC Constructions Ltd. has completed the road construction and is open to traffic. The project met the desired objectives, and the road is functioning well. N For further details kindly contact: TechFab India Industries Ltd. 712,Embassy Centre, Nariman Point, Mumbai – 400021

Techfab India has supplied the entire quantity of Tehrani Drainage Composite within the stipulated time and met all the quality requirements. KMC Constructions Ltd. has completed the road construction and is open to traffic. The project met the desired objectives, and the road is functioning well. N For further details kindly contact: TechFab India Industries Ltd. 712,Embassy Centre, Nariman Point, Mumbai – 400021

Tel: + 91- 22 – 2287 6224 / 6225Fax: + 91- 22 – 2287 6218

Email : info@techfabindia.com

Website :www.techfabindia.com

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.