Through its mechanised processes, Readyfix assures complete consistency in quality and achieving accuracy

Bengaluru-headquartered primary steel manufacturer Sunvik Steels has introduced Readyfix for the construction industry for steel usage, quite similar to readymix as a concrete mixture solution.

The Readyfix offering of Sunvik Steels is a downstream cut and bend service that provides customised solution for construction industry. Sunvik’s new offering besides addressing conventional challenges faced by the construction industry, also aims to enhance construction building quality, efficiency through precision solution, improve inventory control, lower onsite labour, control wastage, improve health and safety at site and most importantly ensure timely construction of project.

Advantages Readyfix

Readyfix addresses the conventional challenges faced by the construction industry like unskilled labour, inaccurate measurements, manual cutting; manual bending, public hindrance, theft and pilferage, project delay and scrap disposal at site. The product also offer superior build quality, improved inventory, improved health and safety conditions at a construction site, avoids wastage at site, thus ushering in a new era of easy procurement. It also ensures freedom of design.

Cut and Bend is the future of steel in the construction industry. Commenting on the benefits of Readyfix, Vinod Kumar, Chairman and Managing Director, String Estates Pvt Ltd says, “Sunvik Steels with its newly launched product Readyfix has excellent steel, precision cut and bend technology. The company has excellent customer service uniquely positioned to scale new heights.”

Mr Nathan, an individual buyer from Bengaluru, says, “Readyfix is very useful as it reduces bar bending time and cost. The staff are very cooperative and guide us very well.”

Apart from offering new-age highly advanced solutions, Sunvik supports its customers with a dedicated and trained workforce and hence is able to minimise problems occurring on the labour front. A key advantage offered through the solution is its ability in bringing down the total construction cost – by minimising labour involvement and material wastage and by speeding up the overall process of construction.

Reports suggest that on an average customer lands up spending a minimum of ` 6,000/- to ` 7,000/- per tonne in the conventional cutting and bending of 40 feet length TMT rebar. Laying the cut and bent steel is another additional expense. According to Sunvik Steels, by using Readyfix a customer can save up to 5 per cent of the costs incurred in cutting, bending and laying and in addition gets the advantage of timely completion of the project and hassle free steel procurement.

Increasing acceptance

Readyfix is all set to revolutionise the primary steel market in India due to its unique advantages. Chairman and Managing Director of Sunvik Steels Pvt Ltd Vivek Kejriwal feels, “The acceptance could take some time as Readyfix will disrupt the highly organised unskilled labour market. Mostly as it happened with the acceptance of the readymix concrete in the construction industry, Readyfix too should in the coming few years stabilise the market as acceptance will grow.”

What makes your readyfix unique?

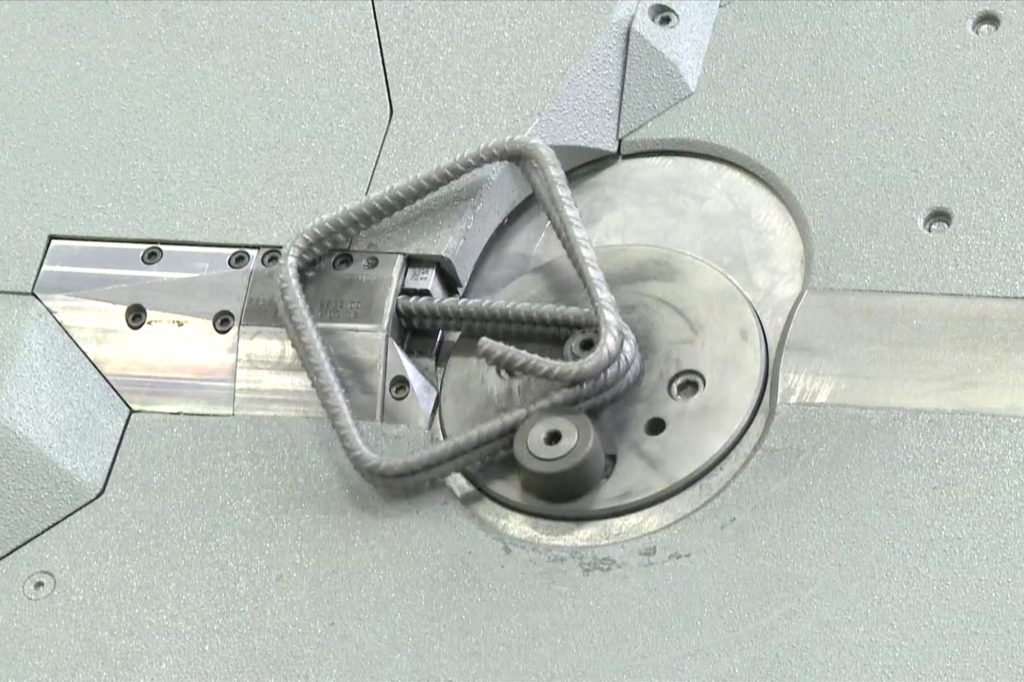

The product is a testament to the high level of sophistication, precision and automation that can provide services over and above the more conventional approach. Apart from its ability in supporting speedy, cost effective and on-time delivery of projects, Readyfix through its mechanised processes assures complete consistency in quality and achieving accuracy. The cutting and bending of the steel items is done as per the client requirements and hence reduces scrap. The Readyfix solutions are in accurate angles and lengths as specified in BS 8666/IS 2502 standards. The 135-degree angle bend and 75 mm length cut helps the stirrups to hold on tightly with the straight rods in columns which in turn will give much more withstanding capacity to the structure, especially to withstand natural calamities like earthquakes. The product is made through fully high-tech automated computerised machines from Italy that cuts and bends steel with absolute precision. With the latest computer-controlled shear-line cutting machine, robotic double bender, single robotic benders and stirrup machinery, the company has the ability to cut and bend bars of diameters that range from 8 mm to 40 mm.

—————————-

The acceptance could take some time as Readyfix will disrupt the highly organised unskilled labour market.

Vivek Kejriwal, Managing Director of Sunvik Steels Pvt Ltd

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.