Nowadays, if we observe, most of the warehouses are built using PEB technique. Let us find out what are the aspects that are making PEB a preferred method for building warehouses on large scale

In earlier days, warehouses were built with traditional brick and mortar construction. However, with the advent of sustainable construction, pre-engineered steel buildings (PEB) technology came into limelight in the warehousing segment and various companies are taking efforts to establish themselves in market.

PEB way for warehouses

PEB technology has now become one of the preferred modes of construction for warehouses being setting up across India. This erstwhile concept in India has now become a widely accepted solution with proven benefits for construction in the Indian environment.

“With eco-friendly construction and fast catching up the growth curve in the Indian market, PEB is the most viable construction solution as it is a green product with very little impact on the environment,” says D Raju, Managing Director, Kirby Building Systems India Ltd.

PEB is also considered as a perfect fit for developing warehousing sites because of the recyclable nature of steel used in the buildings. Kirby has already been designing buildings that meet the green building and eco-friendly construction norms.

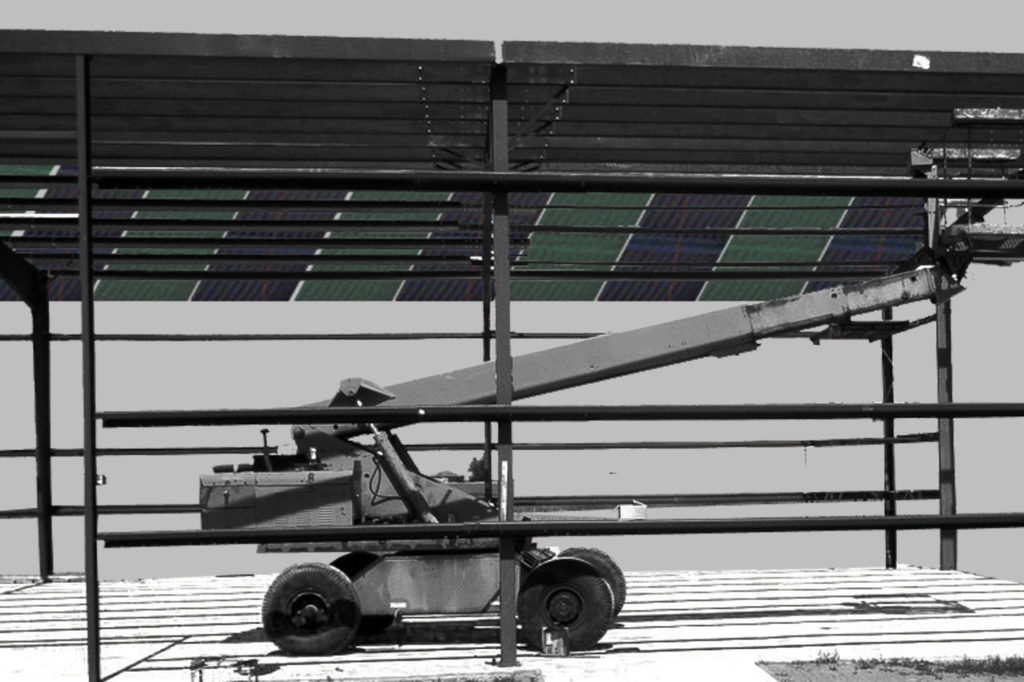

A combination of standard hot-rolled sections, cold-formed sections, profiled sheets, steel rods, etc. are used for the construction of industrial steel structures with PEB systems and are the preferred practices followed in the warehousing industries.

“The most popular configuration of the industrial warehouses currently being used is of PEB which varies in multiple width modules each of about 25-30 metres, having equal nos. of bays varying between 7-10 metres with an eave height around 6-10 metres,” says Anjan Dutta Roy, Vice President, Tiger Steel Engineering India Pvt. Ltd. “In a study between a typical PEB frame when compared with Conventional Steel Buildings (CSB) shows that the PEB provides a better economic output.”

PEB as the name indicates that the concept involves steel building systems which are predesigned and prefabricated. These are produced in a workshop under a global standard quality control by using latest manufacturing techniques.

“The basis of the PEB concept lies in providing the sections varying throughout the length according to the bending moment diagram using non-prismatic rigid frames with slender elements. Tapered built up sections are very commonly used which are made out of thin plates,” informs Mr Roy.

Choosing right material

“Selection of right material of steel depends up on many factors like building occupancy, steel grade, economy, availability, chemical composition, physical property, durability etc.,” says Sanjay Loya, Director, Loya Pre Engineered Buildings Pvt. Ltd.

Today steel is one of the most common materials in the world. Modern steel is generally identified by various grades defined by Standards organisations. For example, the society of automotive engineers has a series of grades defining many types of steel. The American Society for Testing and Materials has a separate set of standards, which define alloys such as A36 steel – the most commonly used structural steel in the United States.

Use of steel

Steel as a material with high strength per unit mass, has an advantage in constructing structures to have large column-free space. An industrial warehouse is a storage building and is usually configured as single storey steel structure with or without mezzanine floors. The designing of industrial warehouse includes designing of the structural elements as it consists of rafter systems or roof truss, columns, purlins or girts, gantry girder and its accessories etc.

“Steel is an alloy of iron and carbon that is widely used in construction and other applications because of its high tensile strength and low cost,” says Mr Loya.

Frames of pre-engineered buildings are made from an extensive inventory of standard steel plates stocked by the PEB manufacturer. PEB frames are normally tapered and often have flanges and webs of variable thicknesses and depth along the individual member.

In regular/conventional steel buildings mill produced hot rolled sections (beams/columns) are used. The size of each member is selected on the basis of the maximum internal stress (bending moment) in the member. Since a hot rolled section has a constant depth many parts of the members are over designed.

Use of steel or metal is much more advantageous while building warehouses. Mr Roy explains the same through following points:

• Many business owners and investors are choosing steel as their material of choice when planning their new warehouse project due to its versatility to meet the storage needs.

• PEB warehouse project layout can avoid any interior load-bearing columns to maximise the useable square footage for storage.

• PEB being an all-steel design generally eliminates any repairing and maintenance concerns that of other building materials suffer from.

• Metal buildings are extremely durable and typically last longer than other types of buildings. They are also immune to termites and are much more likely to withstand extreme weather conditions than other building materials. As a result of this durability, they usually require less maintenance and tend to cost less to insure.

• Steel buildings take less time to build than other types of structures, thus getting a project done a few weeks sooner than normal saves investors quite a bit of money.

Advantages and applications

Generally PEB has number of advantages over the CSB which is widely accepted after obtaining results from various software analysis and literature studies. Weight of PEBs are lighter than CSBs on primary members (about 30 per cent) and secondary members (purlins and girts) made out of coils compared with HR sections used in CSB.

PEB design are more efficient compared to CSB in optimising through various software analysis compare to fewer design aids, hence each project require more time. Connection design is also lesser for PEB when measured against CSB. Foundation support reaction for PEB is also much lesser than CSB, hence light-weight foundation can be adopted which leads to design simplicity and reduction in cost.

“PEB warehouses offer a unique blend of stability, value-engineering, economy and unmatched speed of construction,” says Mr Roy. “Also future expansion is easy and simple for PEB as compared to CSB which is also very tedious and costly.”

There have been early experiments in RCC structures for godowns and warehouses but large spans render RCC options ineffective. In the past the predecessor to PEB was fabricated structural steel shed with trusses and stanchions. But again since this involved usage of standard sections, often left the structure a bit over-designed and cost inefficient. Thus, makes more popular and well accepted concept while choosing the projects such as warehousing.

The PEB buildings are fabricated in such a way that they just need to be bolted to erect, thus reduce the man power requirement and equipment deployment. It can be planned viewing ‘just-in-time delivery’ basis for optimising the logistics and construction schedules to match the warehouse developers’ programme. This helps in bringing down the overall project schedule quite a great extent as compared to CSB or RCC buildings of similar configuration. This results in lesser gestation period on investment and faster ROI. Accurate PEB scheduling provides the investors to suit the dead-lines to start renting out the spaces for faster returns.

The most important aspect of PEB warehouses is that they are made out of largely sustainable structures since the materials used are being sourced from sustainable producers. Financial institutions’ strategy on investments in warehousing business has evolved with large format sustainable and efficient warehouses built to matching global standards sought by global players.

“Warehousing is an ‘investment opportunity’, therefore it needs to be managed through a very optimal management expenses and PEB warehouses are the right answer to it,” believes Mr Roy.

In all, we can say that advantages of PEB include: cost savings, faster ROI, quicker delivery, faster installation, single source responsibility, low maintenance, flexibility in expansion, Architectural flexibility, earthquake resistant, superior quality, etc. and these have become vital for any type of warehouse construction.

PEB structures find their applications in various segments like warehouses, aircrafts hangers, industrial and commercial buildings, multi story buildings, petrol pumps, shopping malls, Restaurants and cold storage structures etc.

Standards and codes

“The lack of standards and codes leaves the customer in a doubt. Presently, in some developed countries like USA, the engineers follow AISC/MBMA recommendations for PEB applications, whereas in India, PEB specific code is yet to be formulated,” says Mr Loya.

The latest IS 800 – 2007 covers steel design by Limit State Method, but still restricted to use concepts for conventional steel design. It is yet to cover the broader spectrum of PEB application.

Solutions offered

Warehouses are increasingly addressing specific requirements for its customers such as offering bare storage, storage with crane facilities, food storage, storage with multi-level stacking and open storage. Kirby India provides a package solution for these types of requirements with its new concept of Rack Supported Warehouses based on the end use of that warehouse. It has already supplied such buildings to many companies.

“Kirby India is the torch bearer for introducing the PEB technology in India,” says Mr Raju. “Kirby’s warehouse buildings are customised to meet the unique demands of the customers. As a result, today Kirby has become synonymous with PEB warehouse buildings in the Indian market.”

Kirby is present in both in PEB and storage solutions and it becomes strategic for the company to provide end to end solution for increasing demand for such type of requirements in the market.

Summary

Advantages offered by PEB have made it more suitable and preferable method for building warehouses. In current market scenario, more than 80 per cent of warehouses are being built with PEB which has taken over the conventional mode of construction.

With eco-friendly construction and fast catching up the growth curve in the Indian market, PEB is the most viable construction solution…

D Raju,

Managing Director,

Kirby Building Systems India Ltd.

______________________________________________________________

Steel is an alloy of iron and carbon that is widely used in construction and other applications because of its high tensile strength and low cost.

Sanjay Loya,

Director,

Loya Pre Engineered Buildings Pvt. Ltd.

_______________________________

In a study between a typical PEB frame when compared with Conventional Steel Buildings (CSB) shows that the PEB provides a better economic output

Anjan Dutta Roy,

Vice President,

Tiger Steel Engineering India Pvt. Ltd.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.