Surface Finishing Equipment Company has introduced two new machines for surface blasting

Surface Finishing Equipment Company is an ISO 9001-2000 certified company and is located in Jodhpur. It has come up with two new machines that are made for effective surface blasting.

Hanger type shot blasting machine

A mega shot blasting machine having 14 wheels station have been manufactured and successfully commissioned by Surface Finishing Equipment Company. The company is an ISO 9001-2000 certified company and is located in Jodhpur. The machine is made for heavy fabricated structures of automobile industry and pre-engineering fabricated structures.

The job is loaded on load bar of automatic trolleys having auto hoisting arrangement. Two trolleys are coupled through load bar for loading of heavy structures. These loaded trolleys carry the job into blast chamber where 14 wheels stations are located strategically at descaling angle. The job pass through the high velocity stream of abrasive thrown by blast wheel stations resulting into thorough single pass cleaning of job. The cleaned job comes out from the outlet vestibule of blast cabinet. The inlet and outlet vestibules are sealed with spring steel rubber vestibule.

The machine is equipped with effective abrasive recovery and cleaning system. The blast cabinet is effectively ventilated by powerful reverse pulse jet type of dust collector unit. The entire operation of machine is sequentially auto managed by PLC system. The machine is eco-friendly and conforms to Central Pollution Control Board (CPCB) norms.

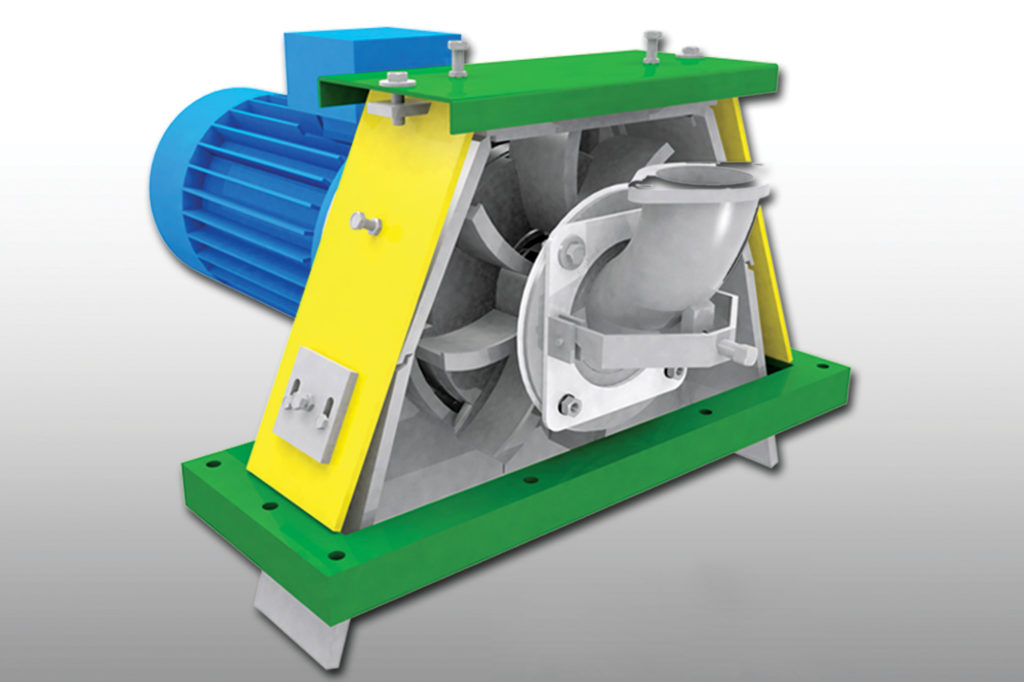

Mini high production shot blasting machine, RBF-1

Surface Finishing Equipment Company has also introduced ‘mini but high production shot blasting machine – rotary barrel type’. This machine is surfex blast wheel and houses a barrel having effective volumetric capacity 1.5 cft. and load carrying capacity 100 Kg. approximately while the barrel rotates, a small size and compact blast wheel throws abrasive on tumbling components inside the barrel.

The shot blast cleaning cycle of components depends up on the initial condition of the components and degree of cleaning required and type of blast media used. The machine can give all types of finish.

The machine is fitted with cartridge type dust collector which constantly removes the dust from the abrasive circulation system and ensures emission standard as per international specifications. An electric timer is also provided for time control operation of the equipment.

The machine does not use costly compressed air and require only 5 HP to operate. The electric controls are centrally located and incorporate all safety features. The machine is designed for shot blast cleaning of small or medium size iron, steel, alloy and non-ferrous castings, forgings, heat treated parts etc. at the lowest possible prices.

The company observes that the wheel blasting machines have very high outputs and it is very important to maintain a consistent degree of efficiency.

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.