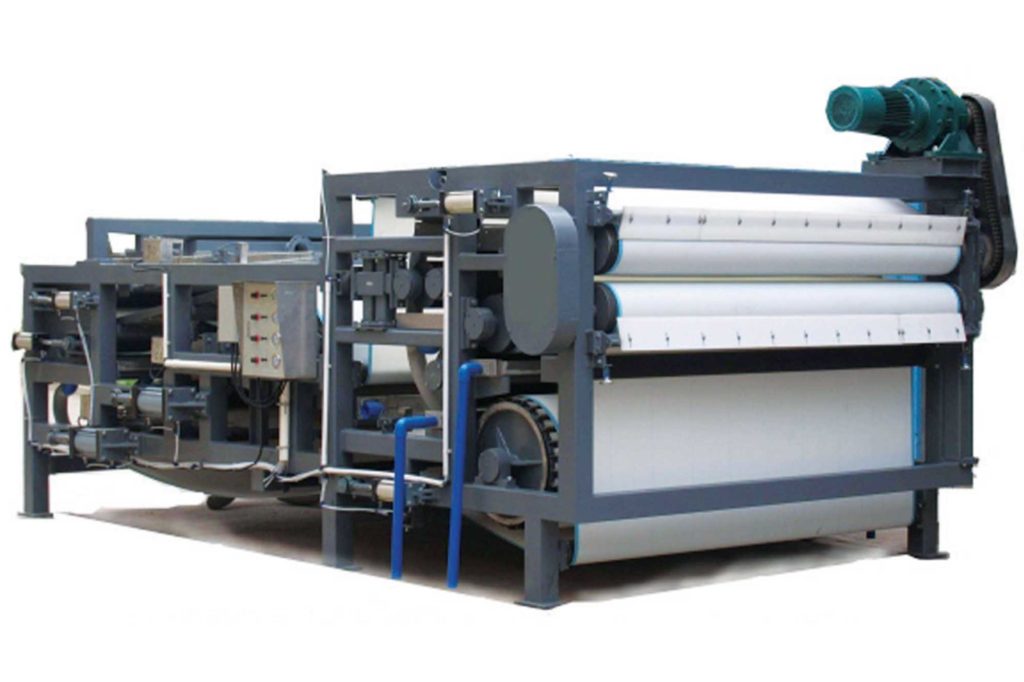

Belt filter press is a continuous sludge de-watring device which uses chemical conditioning gravity drainage and mechanically applied pressure to de-water sludge. First the conditioned sludge is introduced through a hopper to gravity drainage section where thickening takes place through the drainage of free water through the belt. Suspended solids concentration increases in this section. Following this, sludge is subjected to gradual increasing pressure by squeezing opposing belt fabric. The belts are held in place by series of rollers that subjects the sludge to shearing forces as belt pass through a series of rollers that define a serpentine path. These forces thus introduced release additional quantities of water from sludge increasing the solid content further. A continuous water spray keeps the pores of belt get plugged. The sludge cake is out at the out let end.

Features

• Very low power consumption

• Low polymer usage

• Long bearing life

• Consistent cake solids

• Automatic running

• Full enclosure option for odour prevention.

Advantages

• Low life costs

• Process reliability

• Process compliance

• Plant reliability

• Minimal operator input

• Outdoor operation

• Proven cost effective de-watering system.

Applications

• Sewage treatment plant

• Water treatment plant

• Chemical industries

• Pharmaceutical industries

• Mineral industries

• Paper industries

• Food industries.

Contact:

Water 2 People Teknologies,

CB-385B, Mezanine Floor,

Ring Road, Naraina,

Delhi – 110 028

Tele: +91-8447651114/ 8447651116/ 8882787277/ 8882187277

Cookie Consent

We use cookies to personalize your experience. By continuing to visit this website you agree to our Terms & Conditions, Privacy Policy and Cookie Policy.